Thinking of adding spot UV coating to your book cover, but not sure what's involved? We have all the answers right here!

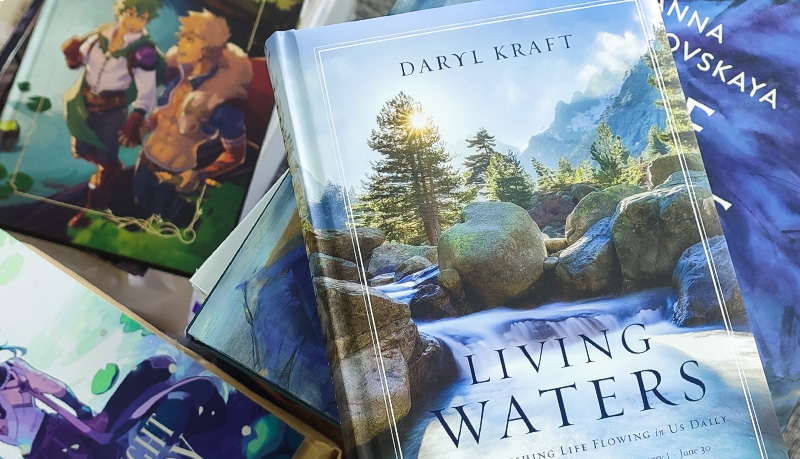

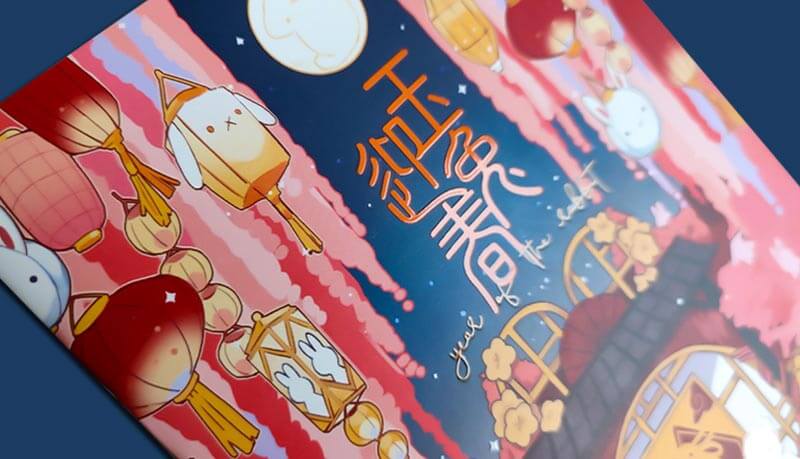

Spot UV coating, a specialized technique applied to certain areas of a printed surface, elevates the aesthetic and tactile appeal of book covers by applying a clear, glossy coating selectively, rather than across the entire sheet. This process accentuates specific design elements, making them stand out, and adds a luxurious depth and contrast to what might otherwise be considered a flat design. Ideal for full-color printing on matte paper or matte laminated paper, spot UV coating seals the color, enhancing protection against fading and augmenting the perceived value of your book.

With book cover design, the compatibility of spot UV printing with various surface finishes, especially matte or soft-touch laminates, guarantees excellent adhesion and an optimal aesthetic result. This finishing technique is both cost efficient and environmentally friendly (it's non-toxic) and stands out as a fantastic choice for authors and publishers who want to make a powerful first impression. Incorporating spot UV in your book cover design demonstrates attention to detail and can also be a strategic move in book marketing, setting your publication apart in a crowded marketplace.

What is Spot UV coating?

Spot UV coating is a finishing method rather than a printing technique, but it plays a pivotal role in enhancing the visual and tactile qualities of printed materials. At its core, spot UV involves:

- Application process: Using photosensitive varnishes which cure under ultraviolet light, leaving a glassy effect. The process, typically used to highlight a specific design element, such as a logo, author name, title, or award medal, makes the applied area shine with heightened clarity. It also makes the surface more resistant to smudging, scuffing, scratching, moisture, and sunlight damage, extending the life of the book cover.

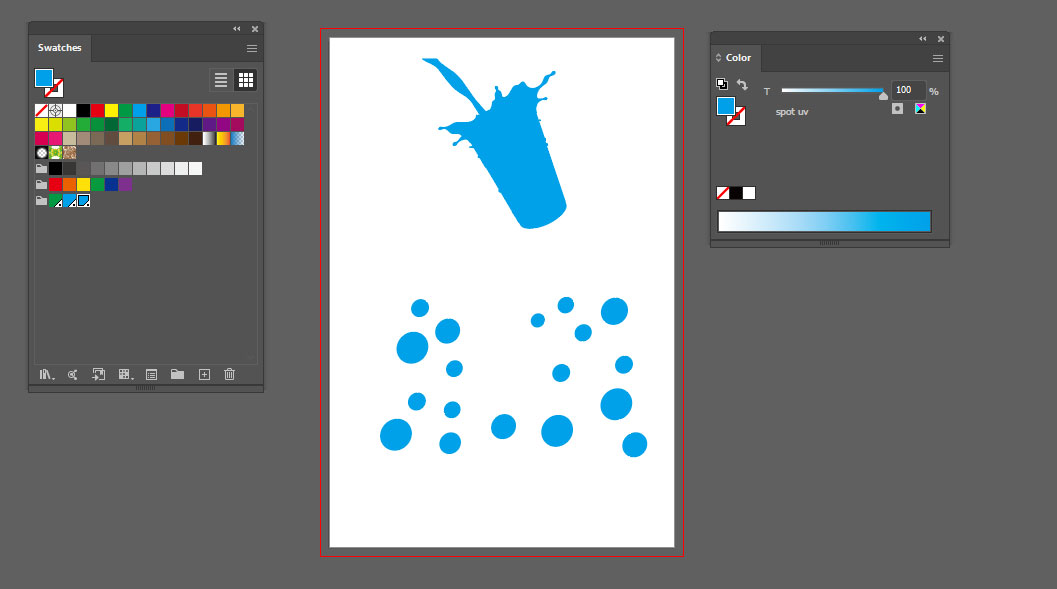

- Precise and versatile: We'll look in more detail at how to prepare your files for printing with spot UV coating. But in short, a mask file dictates the exact areas for the UV coating application, making sure that we can achieve pinpoint accuracy.

- Enhanced design: While it's possible to UV coat the entire surface, applying the varnish only on key elements, or “spotting”, creates a striking contrast with the otherwise unembellished areas. This adds depth and dimension and significantly improves the vibrancy of colors.

Spot UV coating is an excellent and inexpensive way to lift your book cover above the crowd. Relatively simple from a technical and design point of view and adding little extra cost to production, it's a fabulous choice for adding sophistication and durability to your book covers.

How we apply spot UV coating

It might be helpful to you to understand how we actually prepare and apply spot UV coating to your book cover based on your design. So, these are the basic steps and processes involved:

Preparation

- We begin by completing all other printing processes, as spot UV is the final touch before cutting, folding, and binding your book and cover together. So, we'll print the interior and the cover sheet, including a layer of matte or soft-touch lamination which gives the best substrate on which to apply the UV varnish.

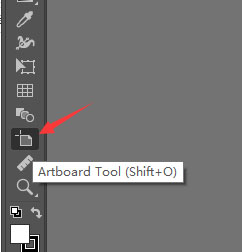

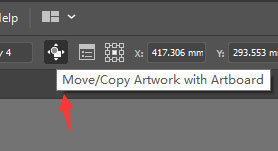

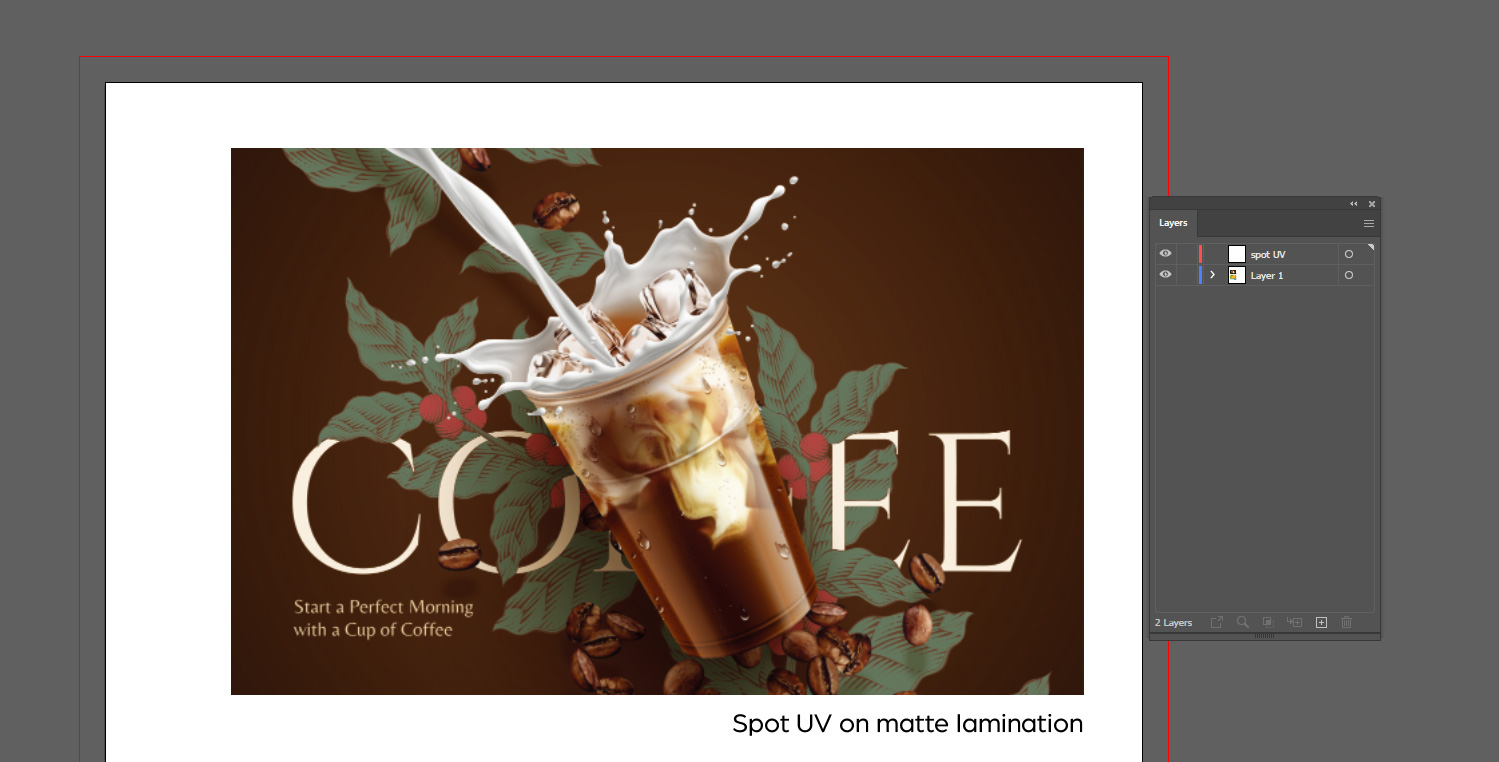

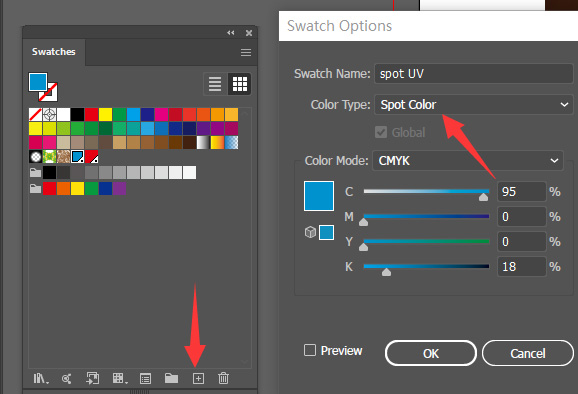

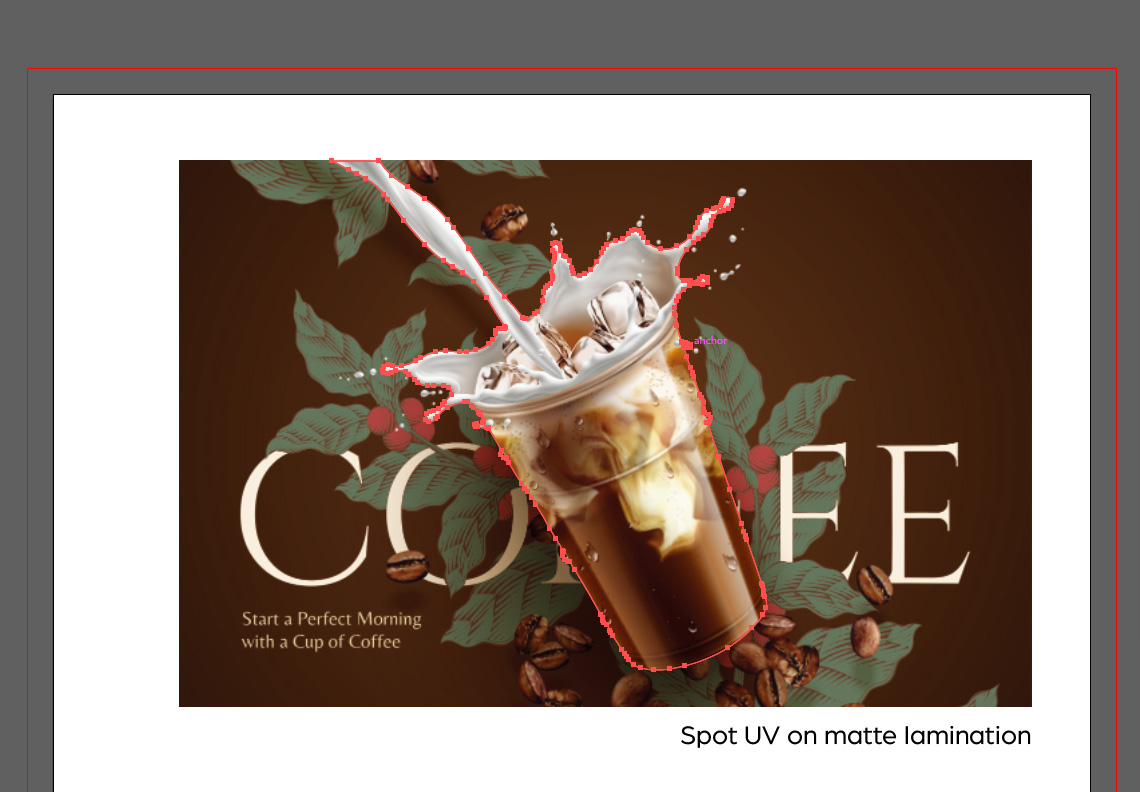

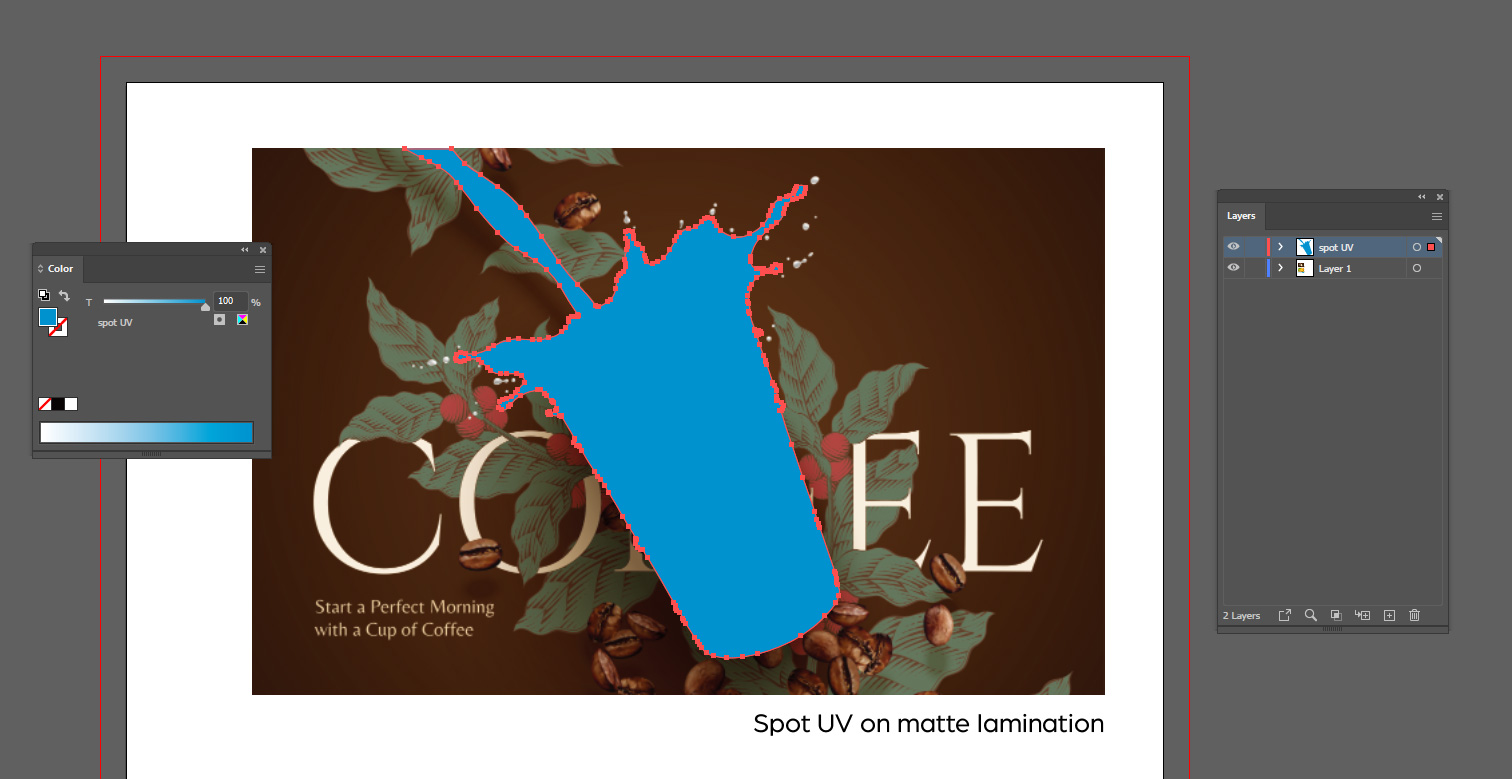

- We manually check your print files for errors and either correct minor issues or work with you to resolve any significant mistakes. For spot UV, a mask file determines where we apply the coating and this file should be vector-based, not raster, to ensure precision. We'll explain this in more detail in a minute.

- We process your PDF files to check and setup your spot UV layer. We'll make sure that you've fixed the spot UV elements on a separate layer above the artwork, assigned a spot color for spot UV and your files are compatible. That's a lot of checks, but it's really just to be on the safe side. We usually encounter very few problems, at least with clients who have collaborated with us from the design stage onward.

Applying the spot UV

- We apply the coating with great care using a uv plate, which is crafted and set based on the vector images and text from your mask file.

- Once we've applied the coating, we expose it to ultraviolet light. This exposure causes the coating to dry and harden instantly, leaving a high gloss finish.

It's as simple as that. As you'll have figured out, the process itself isn't complex and what really matters is getting the design and artwork pre-press set up correctly first. That's why — unless you're working with an experienced book designer — we encourage you to get in touch with us early as possible so that our experts can help and guide you, and generally support you to make the entire process as easy and effective as possible.

Top tips when designing for spot UV coating

When integrating Spot UV Coating into your book cover design, considering the substrate and design elements is crucial for achieving the desired impact. Here are the key considerations:

Substrate compatibility

Choose matte or soft-touch laminates as the base for spot UV application. These surfaces provide the best adherence and contrast, making the spot UV elements really “pop”.

Design considerations

- Use spot UV strategically on larger, solid areas, such as typefaces and logos, to enhance visibility and impact.

- Limit spot UV coverage to no more than 25% of the overall design. This makes sure that the coated areas stand out, maintaining a balance between treated and untreated surfaces.

- Incorporate repeating patterns to create textured effects. These can add depth and interest.

Avoid common pitfalls

- Don't position spot UV elements near edges, folds, or fine details, as these areas may lead to less than optimal results.

- Excessive use of spot UV can reduce contrast, making the underlying design hard to discern under certain lighting conditions. Aim for a balanced application to preserve the design's integrity and visual appeal.

By adhering to these guidelines, you can maximize the effectiveness of Spot UV Coating on your book cover, ensuring a stunning and tactile reader experience.

Technical tips for preparing your artwork files for spot UV coating

We promised we'd explain about the mask file, spot color, and other technical details, so let's do that now.

Preparing artwork files for spot UV

As always, if there's anything about which you're not sure, just get in touch. We pride ourselves on our excellent customer service and will always go the extra mile to make sure our clients have a satisfying experience resulting in superb products. You can contact us via telephone, email, Skype, the online chat, or our contact form. We're here and ready to help!

Talk to us!

Integrating spot UV coating into your book cover design needs thoughtful planning, a creative approach, and a bit of technical know-how to maximize its impact and make sure that the printing process runs smoothly. But by following these guidelines and design tips, and by collaborating with us from the get-go, you can set you — and your book — up for success. Get in touch today to discuss your needs or ask for a no-obligation quote. We can't wait to work with you.