With the help of video, screenshots, and clear text instructions, we show you step-by-step how to prepare your artwork files for printing with special finishing techniques such as embossing, debossing, and spot UV coating.

Creating artwork files ready for printing, particularly when you're incorporating special finishes like embossing, debossing, and spot UV coating, might appear daunting at first. However, with a clear understanding of these techniques and a methodical approach, you can achieve excellent results without too much difficulty or stress in tow. All these finishes can be superb choices for your print designs, whether you use them on books covers, comics, board game components, cards, or packaging. They add a tactile and visual element to your designs, making them stand out and catch the eye of potential customers.

In this post, drawing on decades of success helping thousands of clients all over the world to create perfect print products, we'll walk you through exactly what you need to do to get your design files ready for print when you have one or more of these effects included. Each technique offers distinct advantages: embossing creates a raised effect, debossing impresses a design into the material, and spot UV coating adds a glossy highlight. And, of course, you can combine them in a single design.

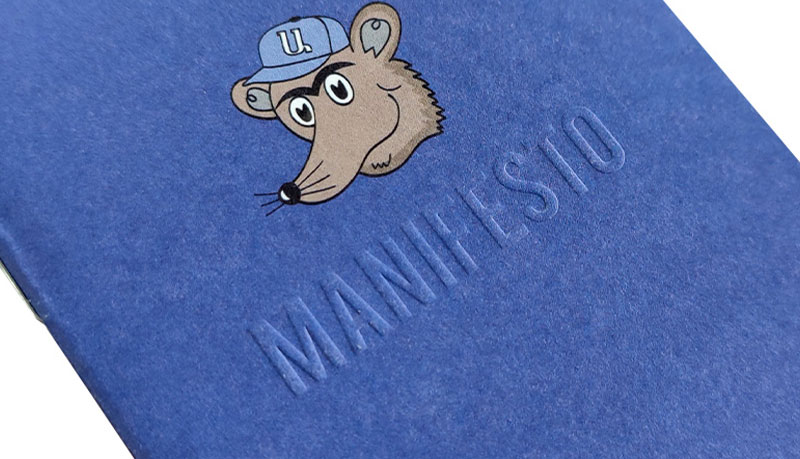

Embossing

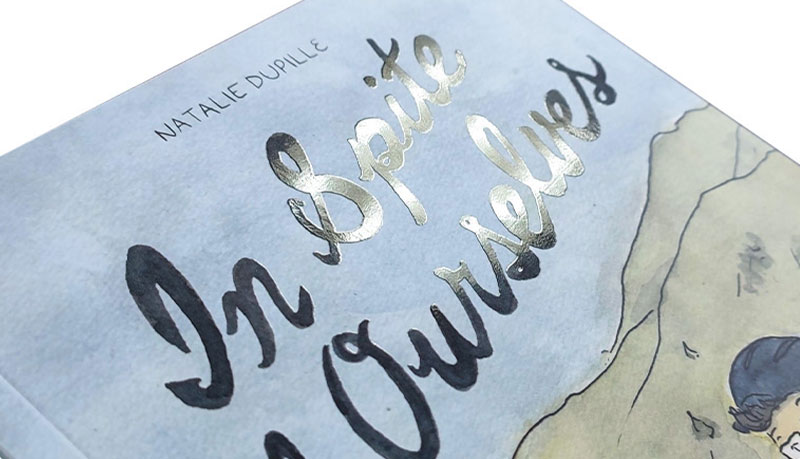

Embossing is a technique that raises a part of the design above the surface of the paper, creating a three-dimensional effect. This is especially useful for highlighting elements like titles, logos, and even works with fairly detailed patterns. On book covers and packaging, for example, embossing can make titles and logos really eye-catching.

Debossing

Debossing, the inverse of embossing, presses the design into the material, creating a recessed effect. This technique is often used to add texture and depth to the design. Less common on book covers—although entirely possible—it's a great technique for boxes and packaging, especially when combined with foil stamping or color printing.

Spot UV Coating

Spot UV coating applies a clear, glossy finish to specific areas of the design, making them shine and catch the light. This technique is perfect for drawing attention to key elements like logos or important graphics. It is frequently used in packaging to create a striking contrast between matte and glossy surfaces and can be an interesting and eye-catching option for book covers and board game components, too.

So, let's get your files ready for printing. We recommend that you watch the above instructional video first as it will be easier to understand what follows once you've seen that. Now, here's what you need to do.

Steps to prepare artwork files for embossing, debossing, and spot UV coating

1. Open your design in appropriate software – Open your design in a vector-based software application such as Adobe Illustrator or Adobe InDesign. These programs offer robust functionality and excellent integration, making them ideal for preparing files with special finishes.

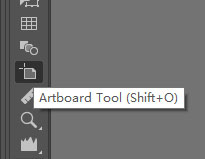

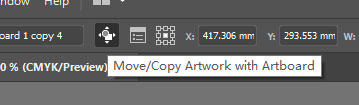

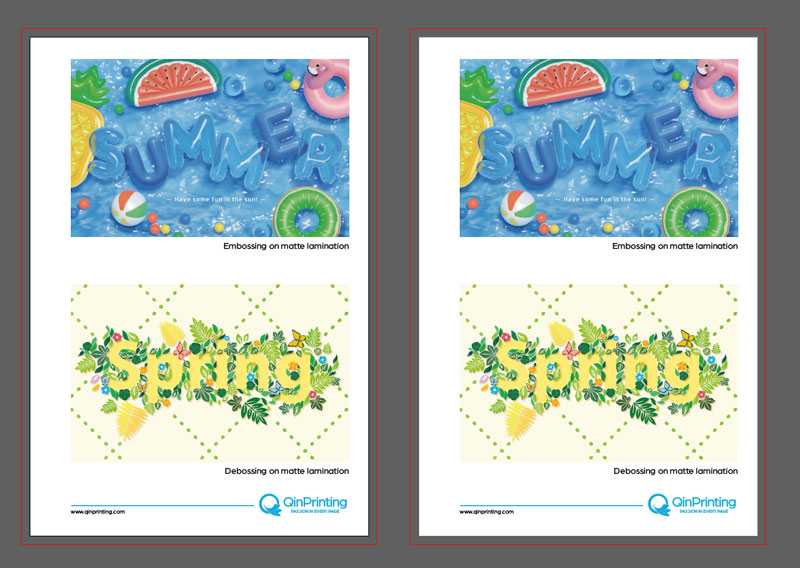

2. Duplicate your artboard – Use the artboard tool to select your current artboard. In the artboard panel, check the “Move/Copy Artwork” box. Hold down the “alt” key and use your mouse to copy a new artboard below the original. Adjust the order of the artboards as needed.

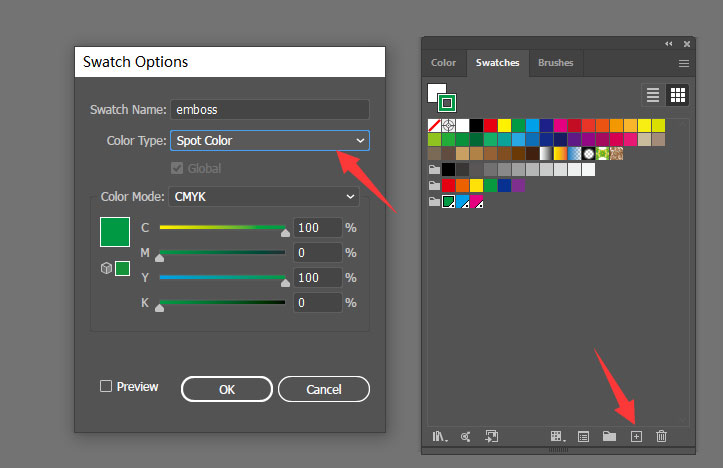

3. Create spot colors – Go to the colors panel and create a new swatch. Give it a recognizable name according to the corresponding process (e.g., embossing, debossing, spot UV). Set the color type to “Spot Color.” Although blue is a conventional choice, any color except white will work to avoid confusion during printing.

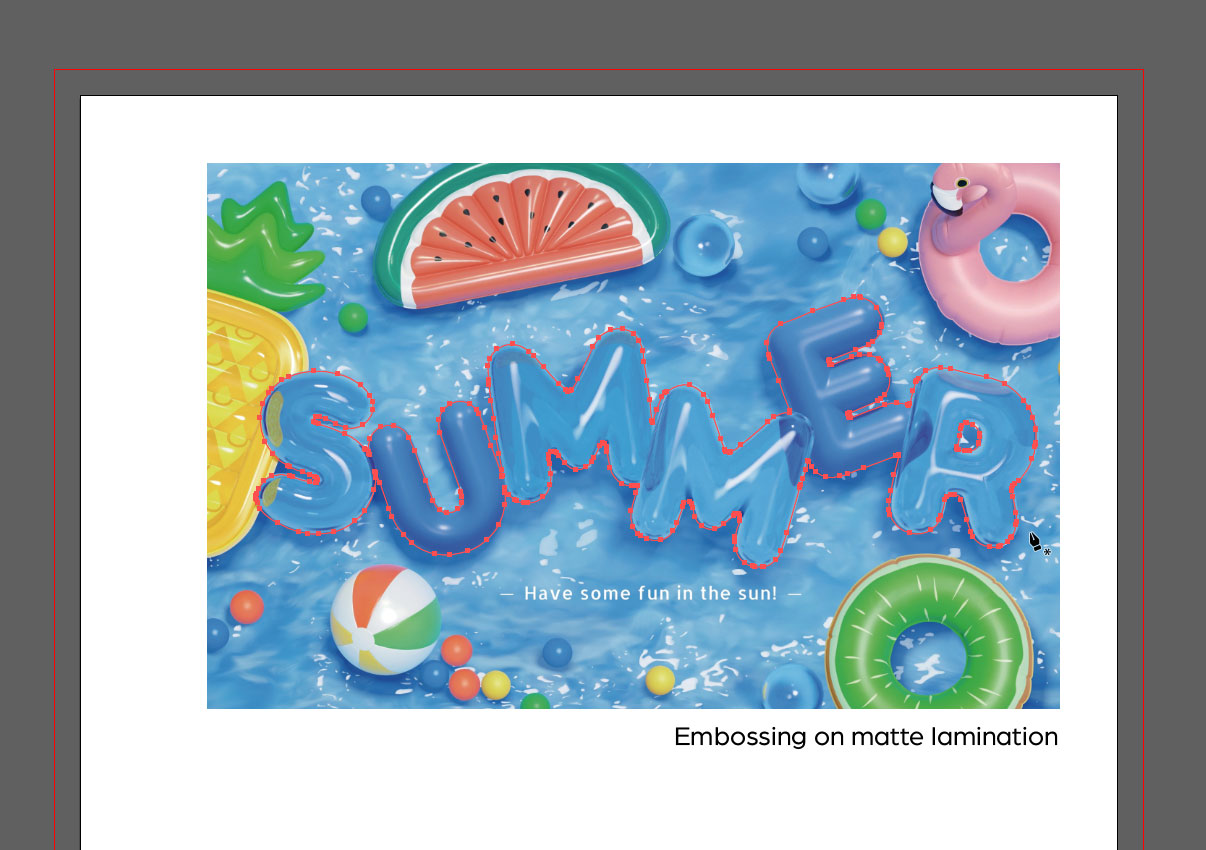

4. Outline the design for special finishes – On the newly copied artboard, use the pen tool to trace the outline of all parts to which you want to apply the special finish. Do this on a new layer, known as the “Mask file,” making certain the original artwork file and the mask file align exactly.

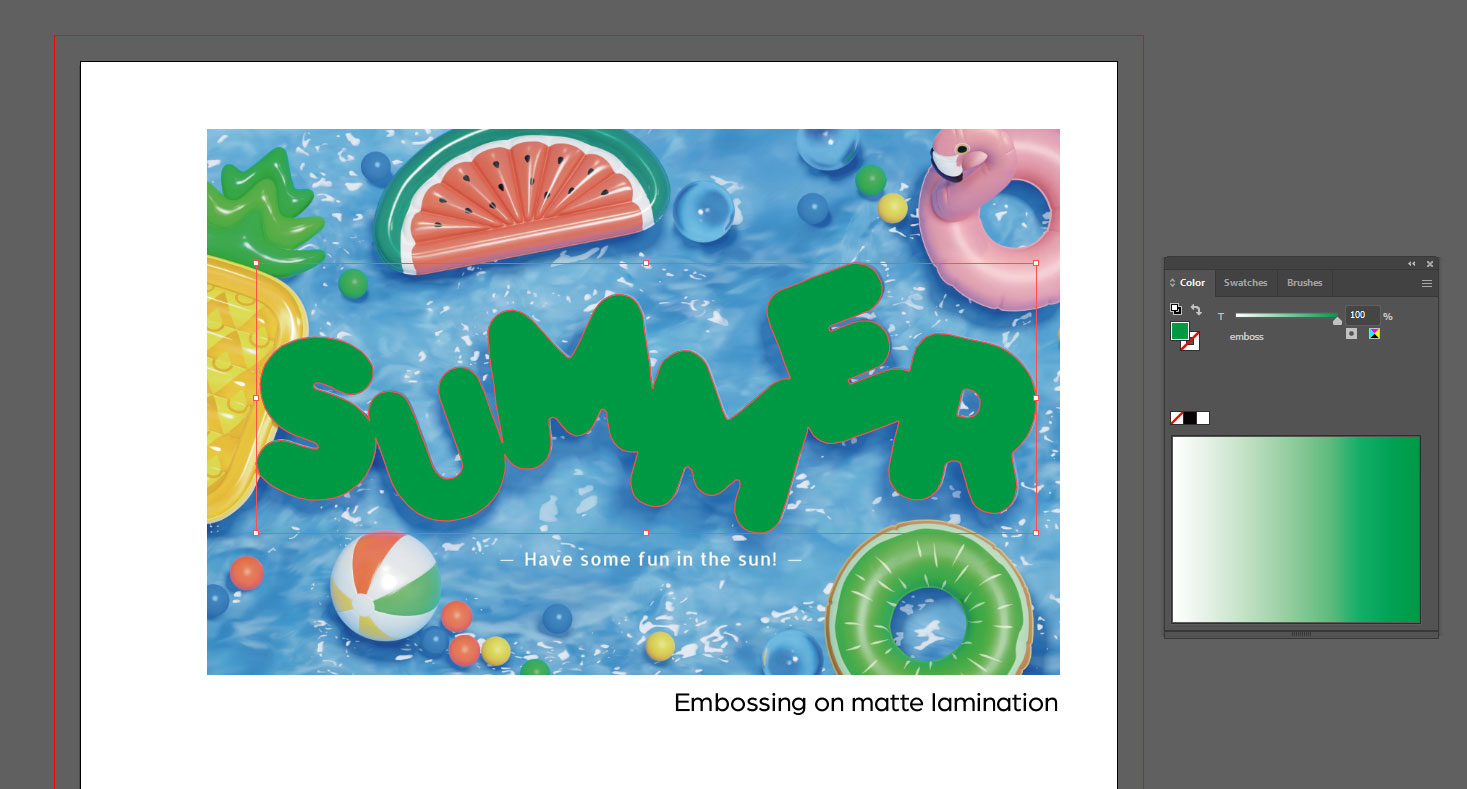

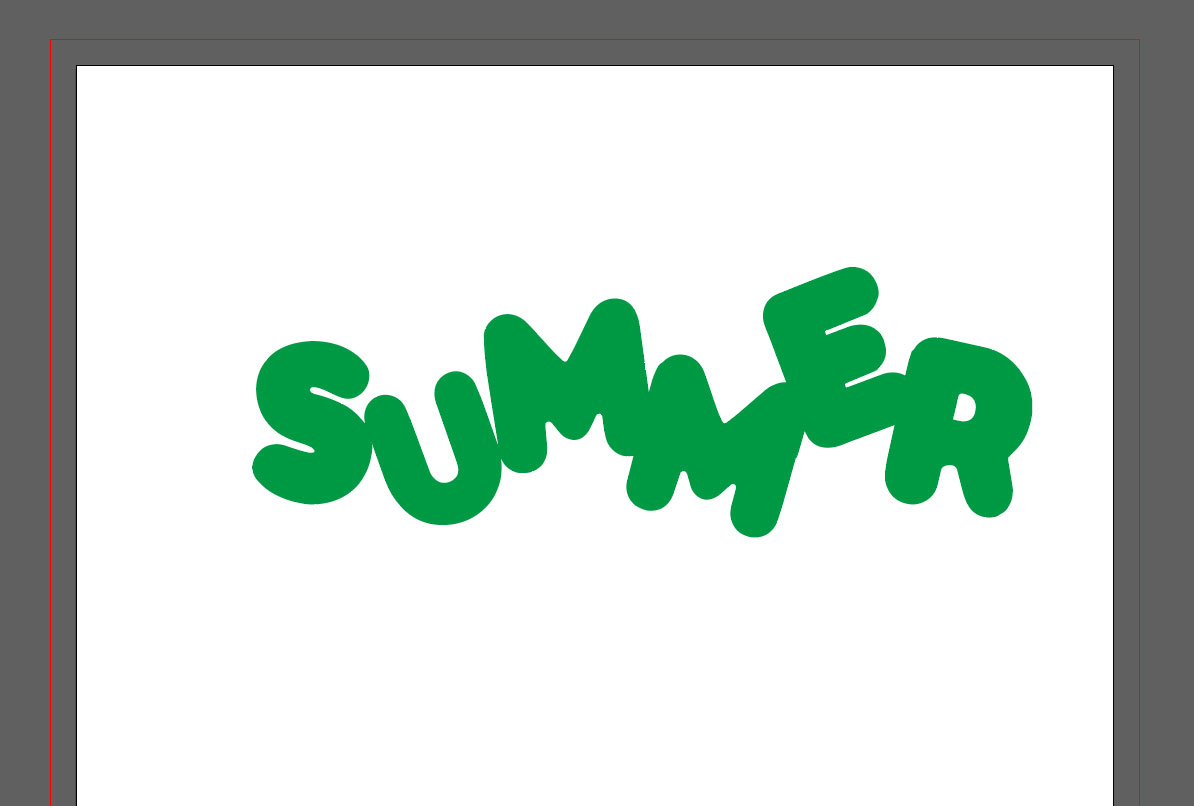

5. Apply the spot color – Fill the outlined parts with the spot color you created earlier. Then, delete all other content on the new artboard except for the spot color areas. If you need to apply multiple special finishes to the same design, create separate mask files and unique spot colors for each finish.

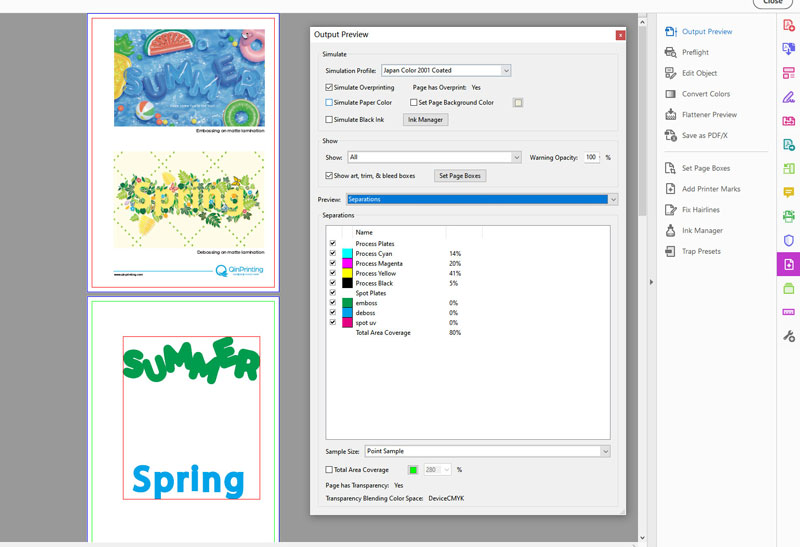

6. Save and check your file – Save your file as a PDF. Choose “PDF” in the file format options and remember to check the “include bleed” box to avoid any white borders after trimming. Open the PDFs in Adobe Acrobat, use “Print Production” and “Output Preview” to check that the spot colors are applied correctly. If everything looks good, you're ready to send the files to us for a fine check by our experts before we set the press rolling!

Advantages of special finishes

Adding a special dimension

Special finishes like embossing, debossing, and spot UV coating significantly enhance the visual and tactile quality of print products. They add a level of sophistication and professionalism that can help your work stand out in a crowded market.

Better branding

By incorporating these finishes into packaging and promotional materials, you convey a sense of quality and attention to detail that can impact positively on how customers and potential customers perceive your brand or product. This is particularly important for luxury and premium products.

Touchy-feely

Tactile elements such as embossing and debossing invite people to interact physically with the product, to touch them and connect. That first tactile contact can make a huge difference to the urge to buy something. Spot UV coating can guide the viewer's eye to specific parts of the design, such as your brand logo, highlighting important information and making your image more memorable.

Applications in various print products

- Comics and graphic novels: Embossed titles and spot UV-coated cover art can make your comic book stand out on the shelf.

- Book covers: Embossed and debossed elements on book covers can add a luxurious feel, making the book more appealing to potential readers and adding a sense of significance to the author's name, for example.

- Board game components: Special finishes on game boards and other components enhance the overall quality of your game, making the components more engaging and enjoyable to see and handle during play.

- Packaging: Spot UV coating on packaging can highlight key branding elements, while embossing and debossing can add a premium touch, making the product more attractive to consumers.

Preparing your artwork files for special finishes like embossing, debossing, and spot UV coating may seem complex initially, but it is an achievable task with the right approach. By following the steps we've detailed above and understanding the unique benefits of each technique, you can create stunning, print-ready designs that look great once printed and really make a difference to your products.

Talk to us! We're here to help.

So, by now you should feel pretty confident that you can prepare your artwork files for printing with special finishes such as embossing, debossing, and spot UV coating. By following the steps we've given you here, you can produce high-quality designs that add something extra special to your print projects.

QinPrinting is an international leader in professional-level offset printing services for both corporate and private clients around the globe. Our worldwide reputation for excellence is built on detailed knowledge and experience within the industry, state-of-the-art printing equipment at our facilities in the famous city of Shanghai, unbeatable prices, rigorous quality controls, and genuine dedication to personalized customer care. We created this guide—with video, text, and screenshots—to make your life as easy as possible when it comes to creating your print-ready special finish files. But if you have any questions still, please get in touch. We're here to help!

Shoot us an email to [email protected] or call us at +1 951 866 3971 and we'll be delighted to discuss your needs.