We walk you through the key paper options, their qualities, and best uses, to help you make the right decision for your needs.

With so many paper options available for print projects — whether you're creating a book, brochure, flyer, catalog, calendar, or even a card game — it can be challenging to choose the perfect one.

For most print purposes, three main types stand out: coated papers (either on one or both sides), uncoated or offset paper, and textured papers like vellum or linen. Coatings also play a big role, as they can enhance durability and visual appeal, with options like gloss, matte, and soft-touch finishes. Beyond type and coating, paper thickness affects both the feel and longevity of your project.

In this guide we'll walk you through everything you need to know to choose the best paper for your unique needs.

Paper coated on both sides

This kind of paper may be art paper, cover paper, or text paper. The coatings are typically either gloss or matte. As the name suggests, these papers are coated on both sides.

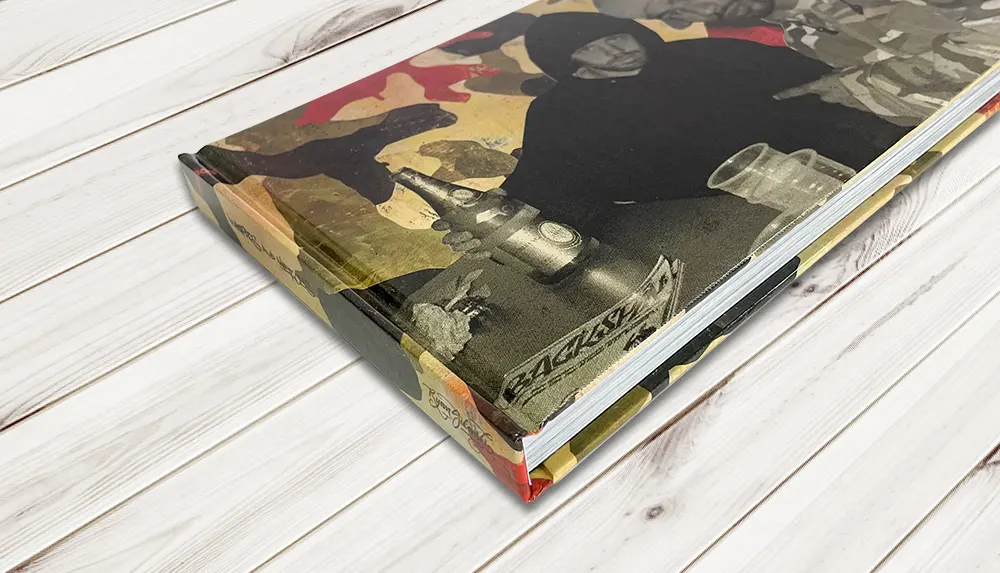

Gloss coating gives a shiny, reflective surface. Matte coating gives a surface which is more light absorbent and softer in appearance. Gloss and matte coated papers are both excellent choices for color or black and white photographic or artwork reproduction.

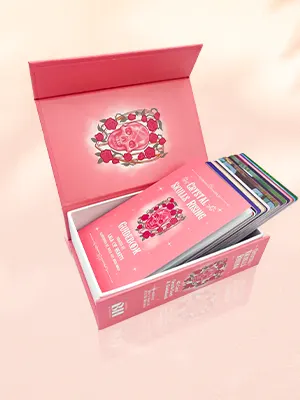

For example, if you are printing a high-end photography portfolio, art book, or coffee-table book, we'd probably recommend gloss or matte paper coated on both sides. Depending on the weight or thickness of the paper, it may be suitable for a softback, hardback, or saddle stitch bound book.

Paper coated on only one side

Paper coated on only one side is often referred to in the printing industry by its shortened name, C1S (coated on one side). The coating may also be gloss or matte, as with double-coated paper. The difference is that they only applied the coating to one side.

As you may guess, this paper is ideal for applications in which only one side of the paper needs to be printed. For this reason, we often use it as the cover paper for a paperback book which will only be printed on the outward-facing side; or the cover for a hardback book which will have the inside glued to the endpapers. That said, it is possible to print on both sides of C1S with the caveat that the quality of reproduction, especially if it is in color, will be different on each side of the paper. If you need to print on both sides of the paper, we usually recommend that you choose paper coated on both sides.

Uncoated paper

Uncoated paper, as the name suggests, is paper with no coating on either side. It is paper in its “raw” state. We sometimes refer to uncoated paper as offset paper, too. But it's the same thing.

Generally, we use uncoated or offset paper for the interior black and white text of illustrated books or for print projects such as coloring books, workbooks, notebooks, and other applications in which it's important that the surface is easy to write on. Gloss paper is not good for writing on as it's not absorbent enough to take the ink of most pens, felt tips will smudge, and it's too smooth to write on with a pencil. We also use uncoated offset paper for calendars, planners, postcards, and thank you cards for the same reasons. Also, comic books with black and white interiors can be printed successfully and economically using uncoated offset paper, even if the cover paper is gloss or matte coated.

Special paper

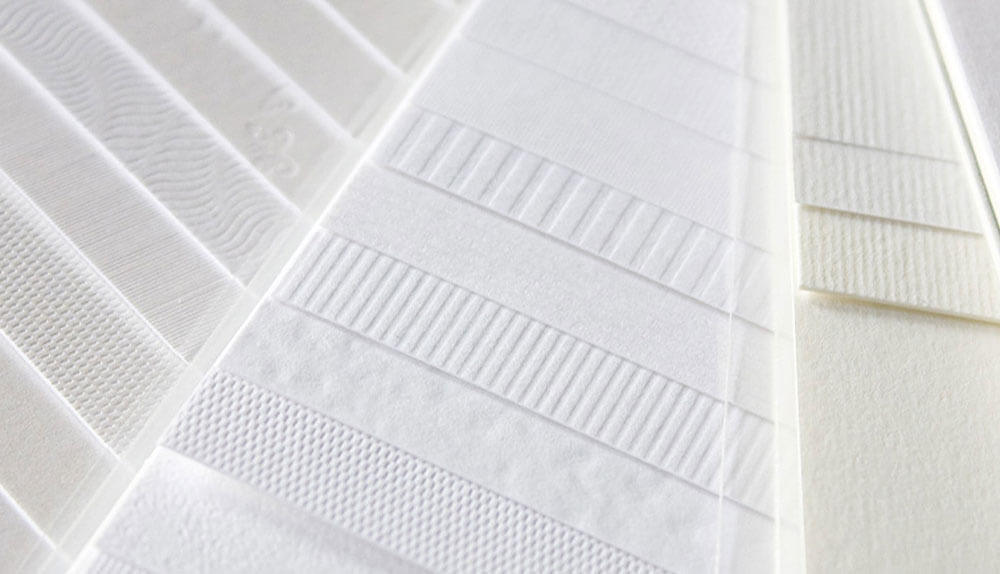

These are not the only paper types, even though they are the most common. We have a range of specialist papers, some of which may also take print. For example, kraft paper, vellum, linen, and colored papers are all good options for specific projects.

However, it's not always necessary to choose a specialist paper to get a specialist effect. There are many ways to achieve outstanding and eye-catching effects with specialized finishes applied after printing on the most common types of paper. For example, varnishing, gloss or matte lamination, soft touch lamination, die-cutting, metallic foil stamping, spot UV coating, embossing, debossing, and more. If you're interested in any of these techniques, just ask us and we'll be happy to explain how they work and help you decide if they're suitable for the print project you have in mind.

Paper weight and thickness

Texture and coating are not the only considerations when choosing paper for a print project. You will also need to think about selecting a paper of an appropriate weight or thickness. This is an area which is often confusing for people not familiar with the methodologies and terminologies of the offset printing industry.

The reason is that we don't measure the thickness of paper in millimeters or fractions of an inch — at least, it's extremely unusual, because it is both difficult and unnecessarily accurate. We usually refer to the thickness of paper as a weight multiplied by an area. In most parts of the world, including China, the standard metric used for paper weight is grams-per-square-metre, shortened to gsm. In the USA and a few other places, the old Imperial weight “pounds”, shortened to lb, is still used. What does all this mean?

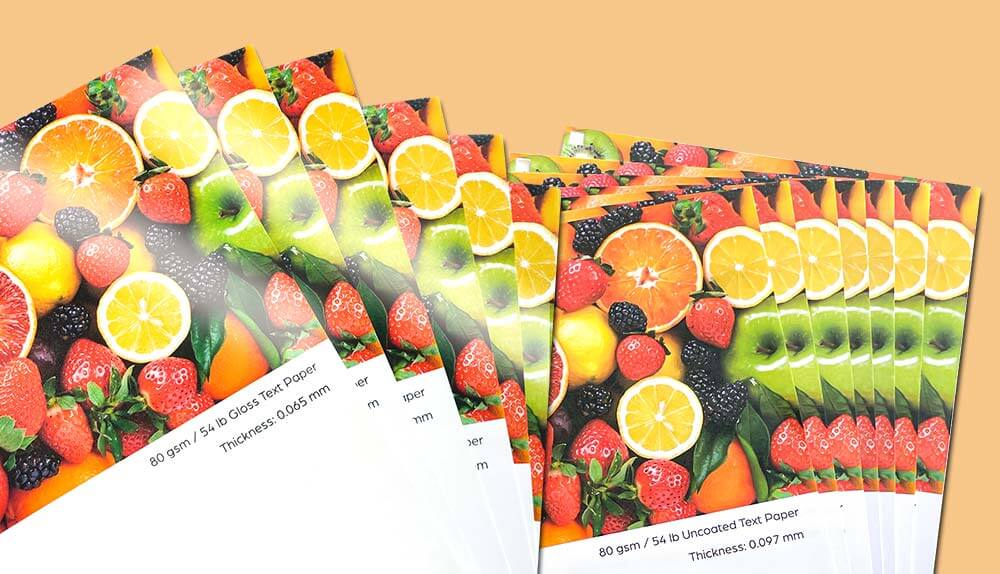

Because paper is often very thin and so practically impossible to measure directly without the use of high-precision scientific instruments, we follow the practice of the paper mills by weighing a “ream” (equivalent to 500 meter-square sheets stacked together) and use the weight as a measure of thickness. If this is still unclear, the best way to get your head around it is to ask us for a paper sample book, which we will happily send you for the cost of mailing it. That way, you can see and touch the different weighted papers to get an idea of what they mean in terms of thickness. If you decide to print with us, we will always advise you on the best paper to use for your specific needs within the limits of your budget.

There are no hard and fast rules about the “right paper” for a project in terms of its thickness. In the end, it comes down to a compromise between personal taste and how much money you have to spend. That said, certain norms and standards exist and in order to meet consumer expectations, it may be wise to follow them. For example, cover paper is usually thicker and coated on one side, interior paper is often thinner and uncoated. Also, the size of the book makes a difference in the choice of paper. A large book will need thicker paper, and a smaller book will need thinner paper.

Choosing the right paper can make a significant difference in the quality and impact of your printed project. Here's a breakdown of common paper weights, coatings, and opacities to help you select the best paper for your needs.

Common printer paper weights

- 300 gsm+: Ideal for high-quality business cards or heavy card stock. Also perfect for retail boxes, providing the strength needed to protect products.

- 270 gsm — 330 gsm: Great for playing cards, with a thickness that ensures durability and easy handling.

- 200 gsm — 300 gsm: Ideal for book covers, offering durability and a polished finish.

- 180 gsm — 250 gsm: Perfect for magazine covers and similar projects needing a sturdy feel.

- 130 gsm — 170 gsm: Great for promotional posters, offering durability without excessive weight.

- 70 gsm — 100 gsm: Commonly used for book interiors, balancing readability and flexibility.

- 80 gsm: Standard office paper, commonly used for everyday printing.

- 35 gsm — 55 gsm: Lightweight paper often found in newspapers.

Guide to paper coating types

Choosing a coating affects the finish and durability of your printed material:

- Varnish: Available in gloss, satin, or matte finishes, varnish is an economical choice for adding a touch of shine, especially to images. However, it provides only moderate protection.

- Lamination: Available in gloss, matte, and soft-touch finishes, lamination provides a durable layer that enhances both the look and feel of your printed materials. Gloss lamination adds a high shine and vibrant color, matte offers a smooth, non-reflective surface, and soft-touch gives a velvety feel, ideal for adding a luxury touch to projects.

- UV coating: Applied as a liquid and cured with UV light, this coating offers enhanced protection and vivid color, available in both matte and gloss finishes, with optional glitter or tinted effects.

- Aqueous coating: Fast-drying and water-based, aqueous coating is environmentally friendly and protects against fingerprints and scuffs, making it an excellent choice for sustainable printing needs.

Guide to paper opacity

Opacity is how much light a paper allows through, impacting its transparency:

- Opacity scale: Paper opacity ranges from 0 (fully transparent) to 100 (completely opaque). For instance, tracing paper has low opacity, while thicker papers offer more privacy and image quality.

- Choosing opacity: Heavier papers generally have higher opacity, making them suitable for projects like posters or book covers where you don't want the other side to show through.

This guide provides a foundation for choosing the right paper for your print project, helping you achieve professional, polished results every time. If in doubt, just ask. We are always happy to help.

Talk to us. We're here to help!

We hope that a quick guide to choosing the right paper for your printing project has been helpful. At QinPrinting we have over 25 years of successful experience in the offset printing industry and have helped thousands of clients just like you to create the finest print products at the best possible prices.

We strive to offer the high quality and professionalism you'd expect from a major international printing house combined with the close attention and personalized customer service you'd normally find in your local print store. We are always willing to answer questions about any aspect of the printing process.

Shoot us an email to [email protected] or call us at +1 951 866 3971 and we'll be delighted to discuss your needs.