End Sheets

While almost everyone who has ever picked up a hardcover book has seen and touched end sheets—also commonly known as endpapers—many don’t realize it! On this page, we introduce you to these essential but discrete elements of book design, what they are, what they do, and when you need them.

What are end sheets

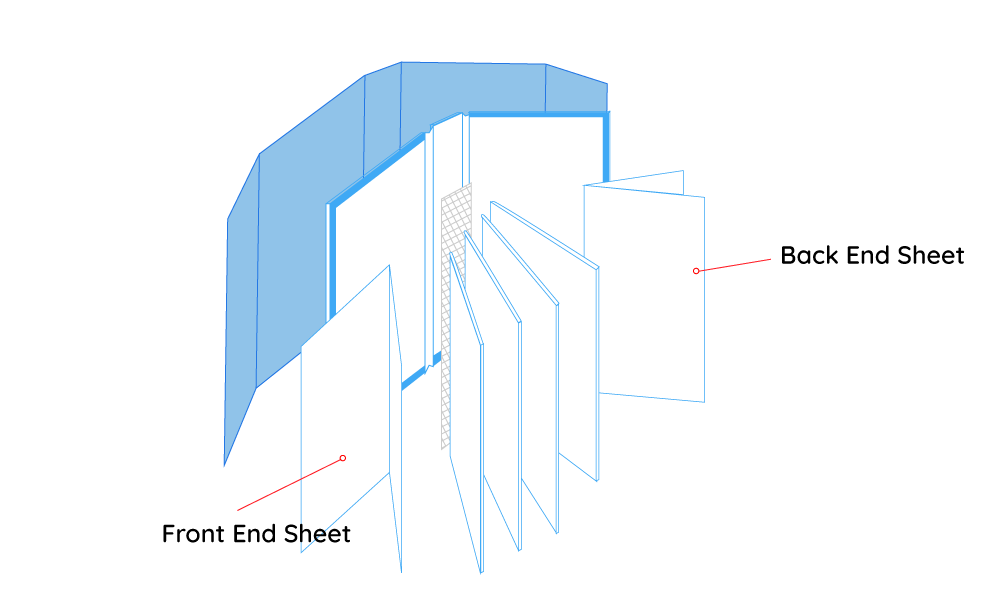

End sheets—or endpapers—are sheets of paper used to fasten the rigid casing of a hardcover book to the block or glued-and-sewn interior pages. Rarely, they are also used in softcover or paperback books, but it’s unusual and only applies to unusual book designs. Each hardcover book includes a four-page front end sheet and a four-page back end sheet, making a total of eight pages. The dimensions of the end sheets or endpapers match the size of the interior pages. End sheets or endpapers aren’t part of the interior book pages, however, but form an essential structure of the binding.

What are the features of end sheets?

Remember that one sheet gives two pages—the front and the back or, in the case of endpapers where the back is folded and glued to the casing and the interior pages and so invisible, one page on the left of the fold and one page on the right. When the readers open the book, the end sheets open with the cover and lay completely flat. There will also be a small space between the end sheet and the interior pages to allow for gluing.

Endpapers have several features related to their functions within the structure of the hardcover binding. These features are both aesthetic and practical in scope. Let’s look at them now.

A clean covering over the hard casing

We make the casing for hardcover from rigid grayboard or similar stiff paper stock. While we wrap the outside of the casing with a printed sheet—or your chosen material such as vinyl, leatherette, or linen—the interior is often left in its raw state beyond the turnover that gives the casing its neat, finished look. But the raw grayboard—which has a purely structural purpose—is not very attractive to look at! But when we glue the endpapers to the interior of the casing, they cover the ugly board and present a pleasing, smooth, and complete appearance. This appearance is especially enhanced if the end sheets are printed or colored.

Add aesthetic value

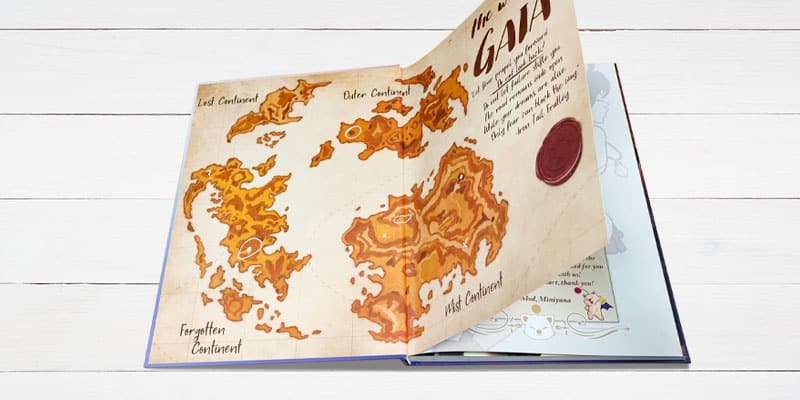

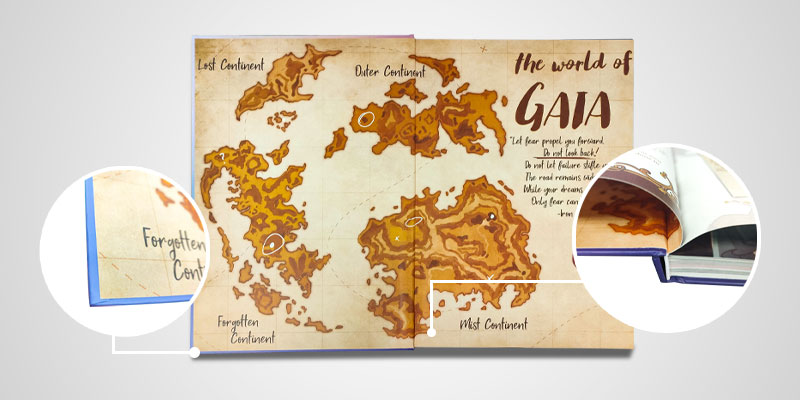

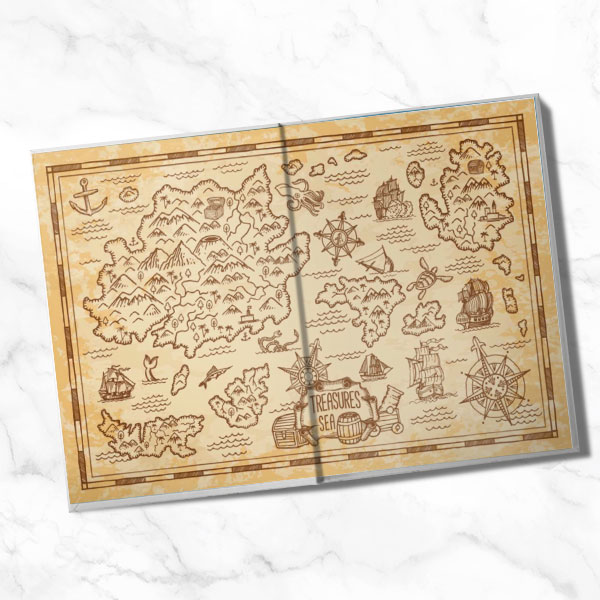

While it’s common to use end sheets which are plain—white, off-white, or some selected color—it’s also possible to print images and patterns on them. You may have seen classic leather bound books with an “ink-and-water” marbling design printed on the endpapers. Endpaper may also be given a textured surface effect or you can opt for a heavier paper stock with a glossy or matte surface.

Secure the binding

When we make a book, the pages are printed on much larger sheets in a particular order which conserves paper and makes sure that when folded and cut, all the pages are collated in the correct order. These sheets are called “signatures”. Once we’ve cut and folded the signatures, we sew them together for strength and flexibility before layering them into what is called the “book block” (all the pages in the right order gathered together) and then we seal the block with a liner and glue the lined block into the casing and secure it with the endpapers. So, a hardcover book without endpapers would soon fall apart. The endpapers keep everything snug and secure for years, or even generations, to come.

It’s also quite common to add single-sheet endpapers to both the back and front of paperbacks. Although they are not a structural necessity, they provide a useful space for author signatures at book presentations. If they are meant for writing and signing dedications we recommend uncoated paper because of its higher absorbency, meaning that pens and pencils will write better on it.

How to design end sheets for your book

We hope it’s clear to you now that the first and final endpapers (at the front and the back respectively) are hidden as they are glued to the casing. For this reason, you can’t add designs to them. Well, you could, but it would be pointless because no one would ever see them! In any case, you may leave all the surfaces of the endpaper plain if you wish. But if you want to add visual designs to them, you can do so on the reader-facing spread and innermost page of the front and back. The single page, remember, will be glued on the innermost side to a depth of about 10 mm. You’ll need to account for that when adding your design. So, make sure to leave a 10 mm gutter to accommodate the gluing area. In terms of what you design for the visible areas of the endpapers, it can be anything printable: colors, patterns, photographs, graphics, lines, even text (although that would be unusual).

When preparing your end sheet design files, keep them separate from your main interior text and cover files. Give them names that make them easy for our printers to identify and understand. So, for example, call them “front-end-sheet.pdf” or “back-end-sheet-single.pdf” rather than something that makes sense to you but may not to anyone else, like, “F1.2/new.pdf” or “DanFinalVersion. pdf”. You may be great friends with Dan and know that he’s your graphic designer, and you may know that it’s the final version of the endpapers; but our printers likely don’t know Dan and it may not be clear to them what it’s the final version of! Clear, logical file naming makes everything easier and smoother for all concerned.

What kind of paper is best for end sheets?

The humble endpapers have a lot of work to do and they’re an essential element of the structural integrity of the entire book. For that reason, we mostly prefer to make end sheets from offset (uncoated) paper because it offers excellent water absorption and adheres firmly to the cover, keeping it really secure.

But the paper you choose also depends on the dimensions of your book. If your book size is 8.5″ x 11″ or less with an interior page count of fewer than 256 pages, then a good option for the end sheets is 140 gsm / 95 lb offset paper. If your book size is larger than 8.5″ x 11″ or the page count is more than 300 pages, 180 gsm / 122 lb offset paper would be better.

So, while on the whole we recommend uncoated paper for endpapers, there are exceptions. For example, if you have an image spread between the last front end sheet and the first interior page, or an image spread between the first back end sheet page and the last interior page, and the interior is made of 157 gsm / 58 lb gloss or matte art paper, then the end sheet paper should be the same as the interior paper. u can color and “texture” the endpapers with printing, or you can opt for uncoated colored and textured papers for a more tactile or stronger visual appeal.

Talk to us. We're here to help!

If you’re still not sure which paper options would be best for your endpapers, the best thing to do is get in touch. Tell us about your book, its size and page count, who it’s for, and how you’ll be storing, displaying, and distributing it and we’ll be happy to give you our best advice, based on 25 years of success in the industry. We’re an expert team with a real passion for print and a genuine commitment to treating each customer as an individual and serving you and your business’s needs first. Talk to us!