Paper Box Measurement

We unpack the mysteries of paper box measurement for your custom packaging designs

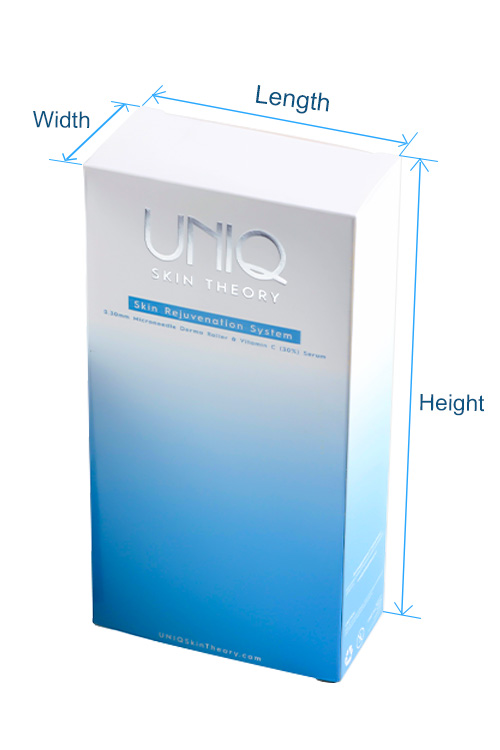

Box Dimensions

When it comes to designing your custom packaging, you must take care to use accurate and precise dimension measurements. While at first glance you may think that there's nothing to it, several important factors require your attention to get it right. Each box has three dimensions and five possible measurements. The dimensions are:

- Length

- Width

- Height (sometimes referred to as depth)

The measurements include these three dimensions, which are measured in simple units such as millimeters (mm) or centimeters (cm), plus:

- Area

- Volume

The area measurement is the total surface space covered by one side of the box. The total area is the sum of all the surfaces. It's measured in units squared (mm² or cm²). Volume is a measure of the entire amount of space inside the box and is measured in units cubed (mm³ or cm³).

While for certain projects, volume and surface area can be important, the fundamental measurements needed to create a viable box design template and accurate dielines are the dimensions of length, width, and height. So, we'll concentrate on these for now. Let's take a closer look at the meaning of each of these dimensions and how to know which dimension refers to which part of your box and your box design.

- Length is always a measurement of the longest side of the top surface of the box. So, imagine you place the box on a table and stand over it, looking down with a “bird's eye” view. The longest side you can see gives you the box's length measurement. It isn't always the box's longest side over all — for example, in the case of a tower-shaped box, in which the length would be shorter than the height.

- Width is always the shortest side of the top surface of the box. So, again, looking down on the top of your box from directly above, the side that isn't the length, is the width.

- Height is the measurement in an up-down direction, perpendicular to the other two.

It may surprise you, but square boxes are rare in packaging design. Most are extended rectangular forms which may be long and flat like a shoe box or a chocolate box or taller than they are wide, as in a box designed for certain household electronics, perfumes, or ornaments, for example. But whether your box is tall or squat, square or rectangular, the key measurements are always the length, width, and height.

Internal and External Box Dimensions

Because boxes are made of material — cardboard, paper, surface coatings, and so on—there's always a discrepancy between the outer and inner dimensions. The outer dimensions will always be a little more than the inner dimensions. This difference may be anything from less than a millimeter to several millimeters, depending on the box's size and the materials from which it's made.

To make sure that there will be sufficient space inside your finished box to hold your products or inserts, you'll need to pay special attention to the internal dimensions. As we've noted, these are always slightly less than the outer dimensions because of the thickness of the materials from which the box is made. So, be sure to mark the inner dimensions clearly in your layout and check that you'll have enough room for your product or insert but not so much that excessive movement inside the box could cause damage.

While you must be careful in your internal measurements, the structural dielines marking where the sheet will be cut usually delineate the outer dimensions of the box. This is because there is nothing left over after the cut line, so this will be the full extent of the material of which the box is made. This is also vital to understand when it comes to designing the artwork for your custom box and fitting it to the template. You may have artwork on only the outside of the box or on both the outside and the inside. The safety zones, trim lines, and bleed for the outer surface of the box must be calculated in relation to the external dimensions, while the safety zones, trim lines, and bleed for any interior artwork must be drawn in correspondence to the internal dimensions.

Surface Area and Volume

In many cases, you may not need to worry too much about surface area and volume. But if your boxes are destined to be stored or displayed in a warehouse rack of known dimensions or an in-store context with shelving of a certain height and depth, then it can be useful to calculate the surface area or “footprint” that your box will occupy to make sure that it fits on the shelving securely. Calculating volume can be important if you have a complex multilayer insert, for example, which houses several products in a set. Fortunately, these calculations are simple.

To calculate the surface area footprint of your box, multiply the measurements of the two sides of the bottom panel of the box together. So, if your box's base measures 10 cm by 12.8 cm, the surface area would be 10 x 12.8 = 128 cm²

To calculate the interior volume of a box (how much space there is inside it) multiply the three inside dimensions length x width x height. So, for example, if the box above was 7 cm high, you would calculate 10 cm x 12.8 cm x 7 cm = 896 cm³. For the overall volume (the entire space a box will occupy during shipping, in a warehouse, or on a store shelf) do the same calculation but use the external dimensions.

Talk to Us!

If you still have questions about box dimensions or any other aspect of custom packaging design — structural concerns, material choices, or artwork support — just get in touch and one of our experts will be happy to help. We have over 25 years success in the industry and counting. It's that, coupled with professionalism, state-of-the-art technology, and a genuine commitment to first-class customer service, that has built our global reputation as one of the best in the business. Let's talk!

Start your packaging project with QinPrinting

Explore all our different packaging choices