Soft-Touch Lamination

What Is Soft-Touch Lamination?

Soft-touch lamination is also known as “velvet”, “cello”, and “peachy” lamination. Lamination is the method by which we stick a transparent soft-touch surface plastic film to the surface of a paper sheet using heat and pressure to bond it to the paper. We can add laminates to just one side of the paper or to both sides depending on the needs of the project in hand and the result you want to achieve. Soft-touch lamination is one of three similar laminates, each with unique properties and effects. The others are gloss lamination and matte lamination.

Manufacturers produce laminates in several thicknesses, ranging from near-rigid sheets to very thin, flexible ones. Polyethylene Terephthalate (PET) is the most used to manufacture heavier laminates, while the lighter ones are frequently made from Ethylene-Vinyl Acetate (EVA). PET can be recycled with ease and it's often manufactured from pre-existing recycled PET products. Because of this “closed loop” process, it's thought of as among the most environmentally friendly plastics. EVA is rarely recycled at the moment. But recently, biodegradable forms of the material have been developed and are becoming increasingly available in the marketplace.

Similar to matte lamination, soft-touch laminate gives a subtle, velvety sheen to the printed page. But it doesn't offer as much protection against wear-and-tear as either gloss or matte versions. In fact, it can be rather more prone to scuffing and marking with fingerprints, for example. But despite these practical limitations, soft-touch lamination is a popular choice for upmarket, high-end print products because of its soft appearance and delightful texture. To the touch, it's like velvet or suede. One important factor to bear in mind, however, is that we can only do soft-touch lamination on paper that's thicker than 105 gsm. With thinner paper, it doesn't work.

The Advantages of Soft-Touch Lamination

Soft-touch lamination may or may not be the best choice for your print product. Much depends on the type of product it is, the market it's aimed at, and how much you have to spend. Soft-touch lamination is more expensive than either gloss or matte alternatives and is usually associated with luxury goods. With that in mind, let's look at the primary advantages of matte lamination.

- The “velvety” surface that soft-touch lamination produces enhances your printed materials and gives the page a sophisticated, luxuriously tactile look and feel.

- While soft-touch lamination offers notably less protection against handling and environmental conditions than its gloss and matte counterparts, it still affords some protection and certainly more than no lamination at all.

- Soft-touch lamination works well combined with other special finishes such as metallic foil stamping, embossing, and spot UV coating, which really “pops” on a soft-touch background.

- It adds significant perceived value to your product, making it more likely to be kept, treasured, enjoyed, and shared.

- Soft-touch lamination extends the useful life of printed materials compared with unlaminated products.

- Soft-touch lamination lends your print materials a classy, high-end look and feel that's appealing to the senses.

These are just a few of the advantages of soft-touch lamination, which make it a popular option for any project aimed at the upper end of the market, from books and catalogs to board games, custom paper boxes, and more. But other options might still do the job for you, so let's compare soft-touch with the other most popular lamination choices: gloss and matte lamination.

Soft-Touch Lamination vs Matte Lamination vs Gloss Lamination

Matte and gloss lamination both protect printed surfaces from the wear-and-tear of repeated use, although matte lamination is less resistant to dampness, scratches, and scuffs than its glossy counterpart. As we've seen, soft-touch lamination also offers protection, but a little less than either gloss or matte. But the aesthetic and tactile properties of soft-touch lamination more than make up for the milder protection it offers if it's a high-end, luxury look that you're after. Whereas gloss is shiny and bright with a super-reflective surface and matte lamination softens colors and graphics, it's soft-touch lamination's appeal to the touch that marks it out as something extra-special.

These qualities of soft-touch lamination make it the first choice for luxury print materials that need a more sophisticated presentation compared to the super-shiny surface you get with gloss and the less tactile results offered by matte. Choosing between gloss, matte, and soft-touch lamination is an important decision, but there's no universal solution to which is right for your product. Several factors will influence your choice. But here are some of the most popular applications of soft-touch lamination to give you a better idea of how many of our clients choose to use it.

Popular Applications for Soft-Touch Lamination

We can apply soft-touch lamination effectively to a wide range of print products. What it does is elevate those products above the run-of-the-mill and position them in the affluent market sector. So, let's see how it alters the appearance of several popular printed products.

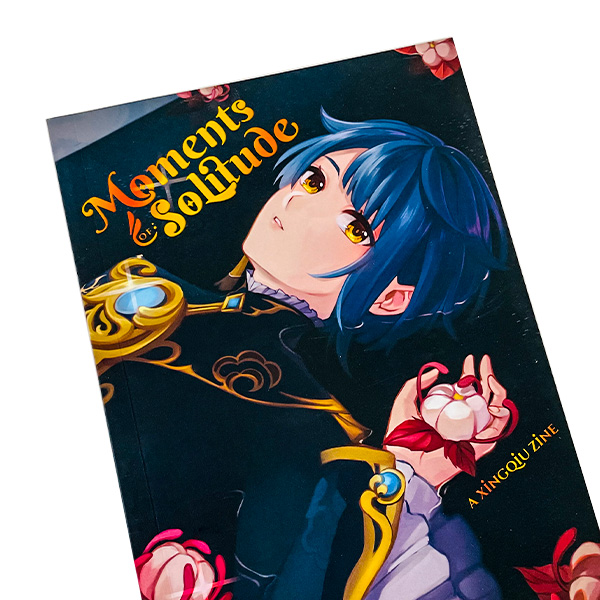

- Art and coffee-table books—the essence of the art or coffee-table book is its role as a style statement. These books are lavishly illustrated with high-quality art reproduction or photography. While gloss or matte may be the best choice for full-color interior pages, soft-touch lamination on the cover will seduce the eye of the viewer and lure them in with its sophisticated appeal.

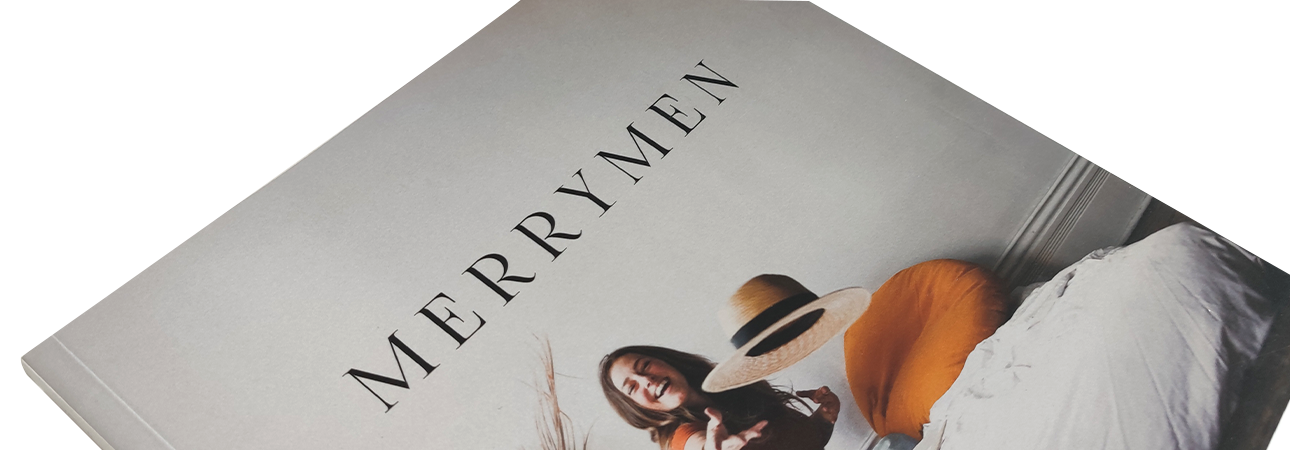

- Luxury product catalogs—soft-touch lamination is a good choice for catalogs in the luxury end of the market designed to appeal to an affluent demographic whose sense of taste and style demands the highest quality and attention to detail.

- Custom printed boxes—another way to use soft-touch lamination to wonderful effect is on the outer surface of luxury custom printed boxes. Soft-touch lifts the box beyond a mere packaging solution and integrates it seamlessly with the aspirations of your customers and the quality of your products.

- Deluxe board games—board games are designed and sold to appeal to various demographics. At the luxury end of the market are deluxe board games made with the finest materials and created to appeal to the wealthiest consumers. For a deluxe edition of any game, a soft-touch laminated board or box surface would add that extra-special presentation the market requires.

We hope the above examples will help you appreciate the special qualities of soft-touch lamination and its appeal. It's more expensive than other options, but not prohibitively so, and if the luxury market is your target, it will probably give you an excellent return on your investment.

Need More Help? Talk to Us!

Choosing between the various lamination options is an important decision which has a significant impact on the appearance and quality of your finished printed product, the design process, and the price. If you're not sure which option is the most suitable for your needs, the best thing to do is to talk to us. With over 25 years' experience under our belts, the latest offset printing technology at our fingertips, a vast knowledge of paper, coatings, finishes, and laminates of all kinds, and a genuine commitment to customer service, we'll be happy to give you the best advice to help you choose the perfect cover surface for both your print project and your budget. Get in touch today for an informal chat or a no-obligation quote. We can't wait to work with you!