Custom Game Card Printing

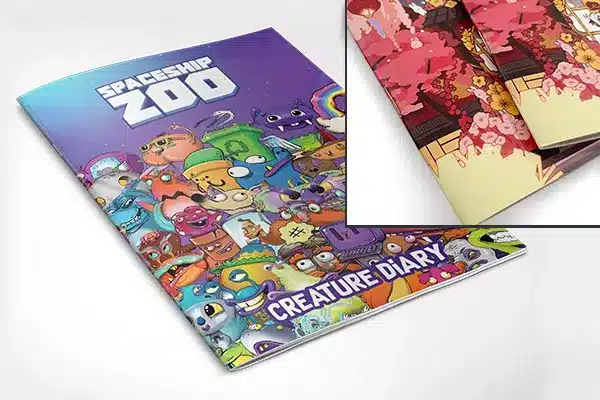

QinPrinting offers professional custom game card printing services for publishers, designers, and independent creators worldwide. Whether you’re producing custom card decks, board game cards, character decks, or collectible trading cards, we provide full-service support from design to delivery. We deliver durable, precision-cut cards with professional finishes at competitive prices.

With over 25 years of offset printing experience, we support short and long runs, custom sizes, full-service packaging, and Kickstarter and other crowdfunding campaigns. Our team is here to help you print game cards that look great, handle well, and stand up to repeated use. We specialize in custom trading card printing as well as traditional game card production for tabletop and educational formats.

Game Card Instant Quote

Paper and Cardstock Options

Choosing the right cardstock is essential for the look, feel, and function of your game cards. We print on high-quality materials designed for durability, color fidelity, and handling. Our most popular materials include:

| Paper | Weight | Thickness (mm) | Thickness (pt) |

|---|---|---|---|

| Premium Cardstock | 250gsm | 0.28mm | 11pt |

| Premium Cardstock | 300gsm | 0.36mm | 14pt |

| Premium Cardstock | 350gsm | 0.405mm | 16pt |

| Black Core Paper | 310gsm | 0.325mm | 13pt |

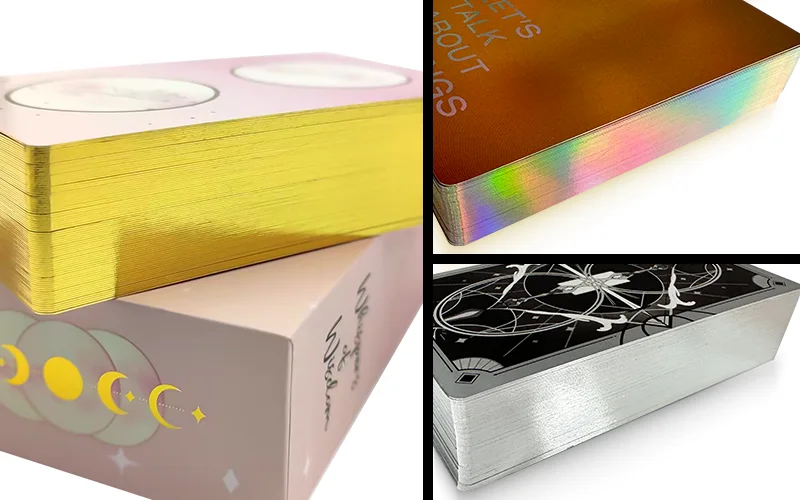

Specialty Cardstock

We also offer unique custom finishes for collectible, promotional, or premium decks:

Holographic cardstock

Reflective foil with dynamic rainbow effect

Silver cardstock

Adds a metallic silver sheen

Gold cardstock

Metallic gold finish for luxury appeal

Contact us to request samples of any specialty material. Choosing the right cardstock can enhance gameplay, improve visual impact, and support specific use cases like collecting or tournament play.

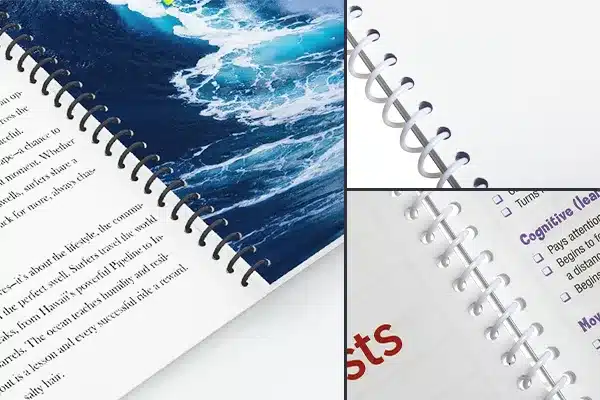

Surface Finishes and Corner Styles

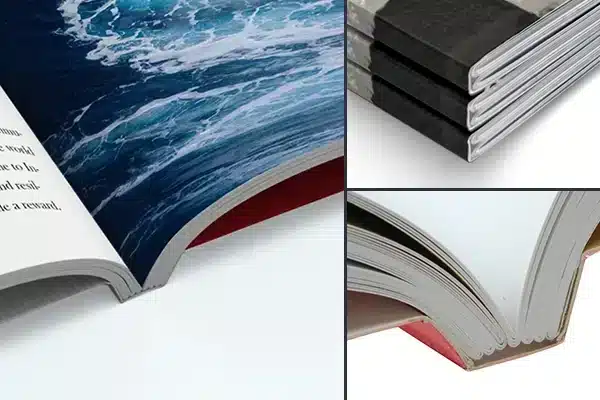

Finishing options enhance the appearance and lifespan of your game cards while giving your design a polished, professional look. Enhance the look and feel of your game cards with protective coatings and specialty effects. Most cards are laminated or varnished on both sides.

A non-glossy coating on both sides that offers a textured feel.

A glossy coating on both sides with a subtle texture.

A smooth, velvety matte film applied to both sides, offering durable, non-reflective finish.

A shiny film applied to both sides, giving the card a sleek, high-gloss appearance.

A glossy finish applied to specific areas for a bold and distinct look.

Metallic gold foil pressed onto the card for an elegant, eye-catching detail.

Metallic silver foil applied to the card, adding a sleek, reflective accent.

Raised designs for added texture and elegance.

Metallic foil applied to the edges of the card, creating a premium and polished look from every angle.

Printed on holographic paper, which reflects rainbow-like colors when viewed from different angles.

You can choose rounded or square corners to complete your custom deck of cards.

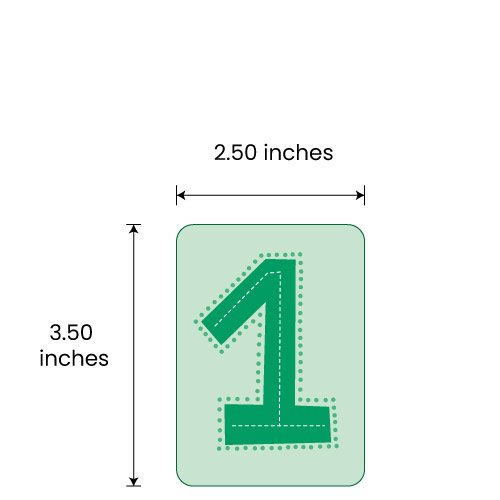

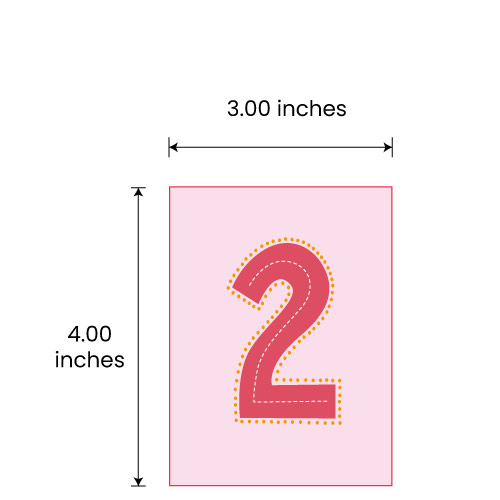

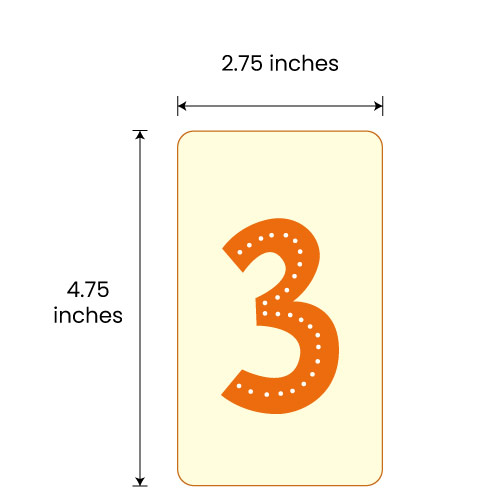

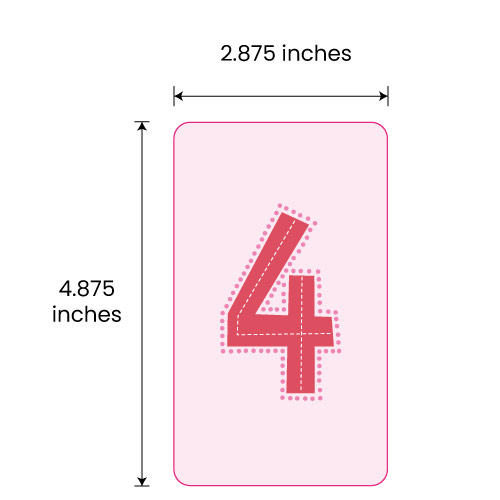

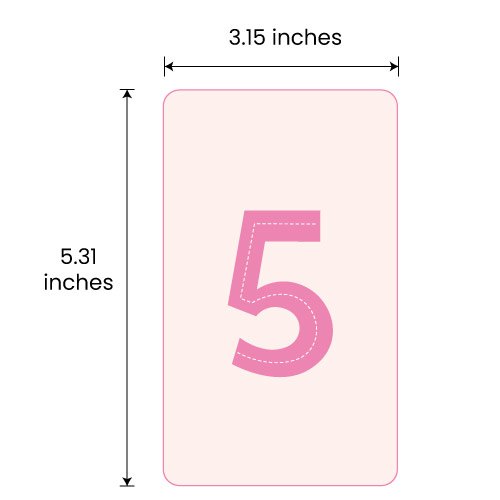

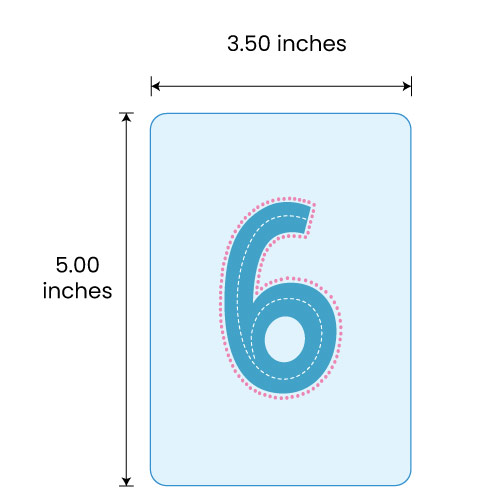

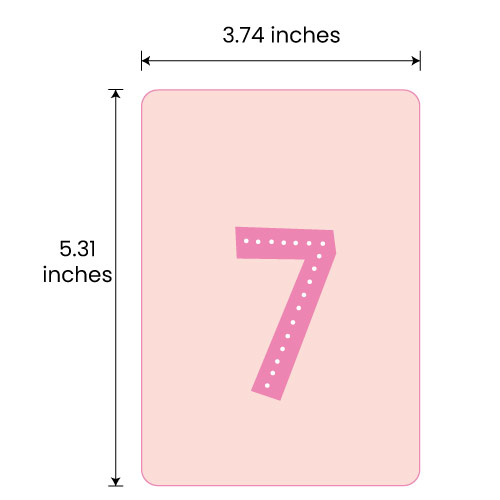

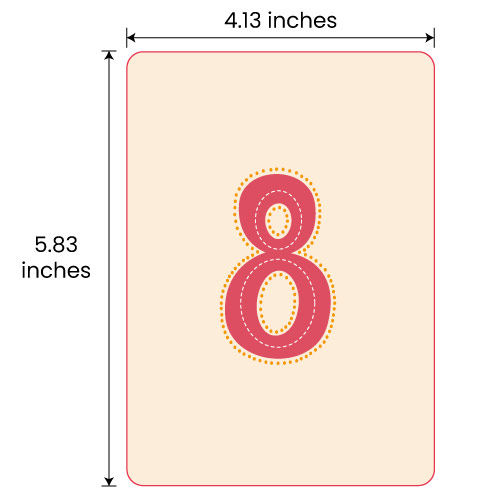

Game Card Sizes

Game card size affects handling, shuffling, storage, and visual design. We use precision die-cutting to shape each card. Standard sizes are available using pre-made molds, which reduces cost and turnaround time. Custom sizes and shapes are available for a small additional tooling fee.

If your game includes multiple card sizes, we can produce and collate them into a single package. Selecting a standard size from our existing molds keeps costs lower and speeds up production.

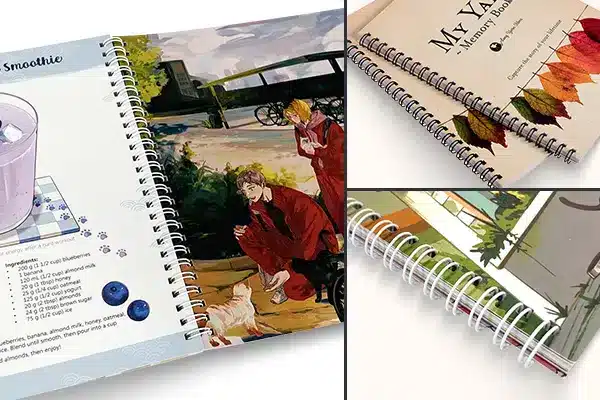

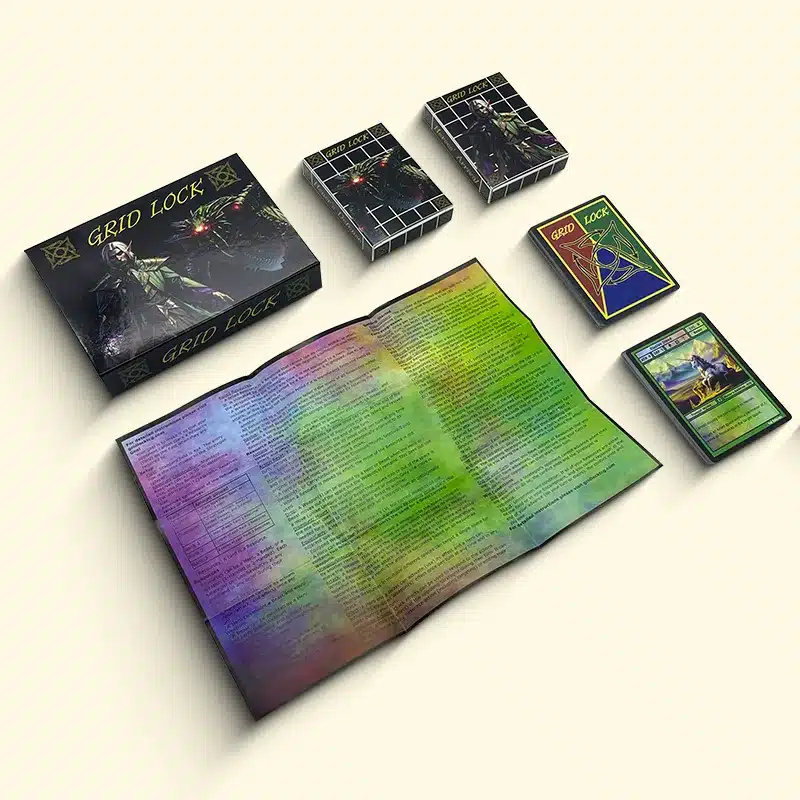

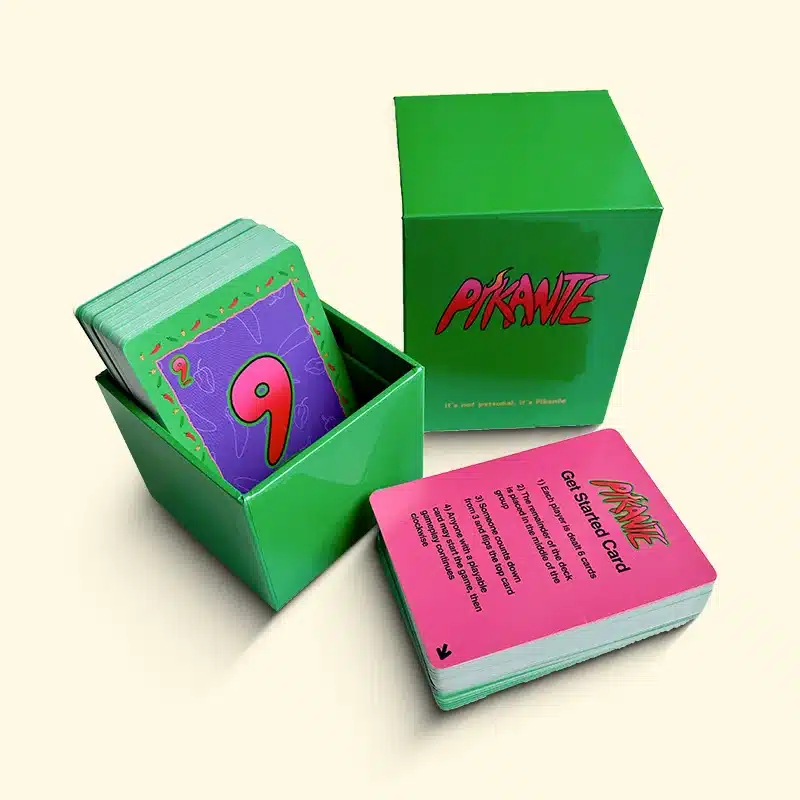

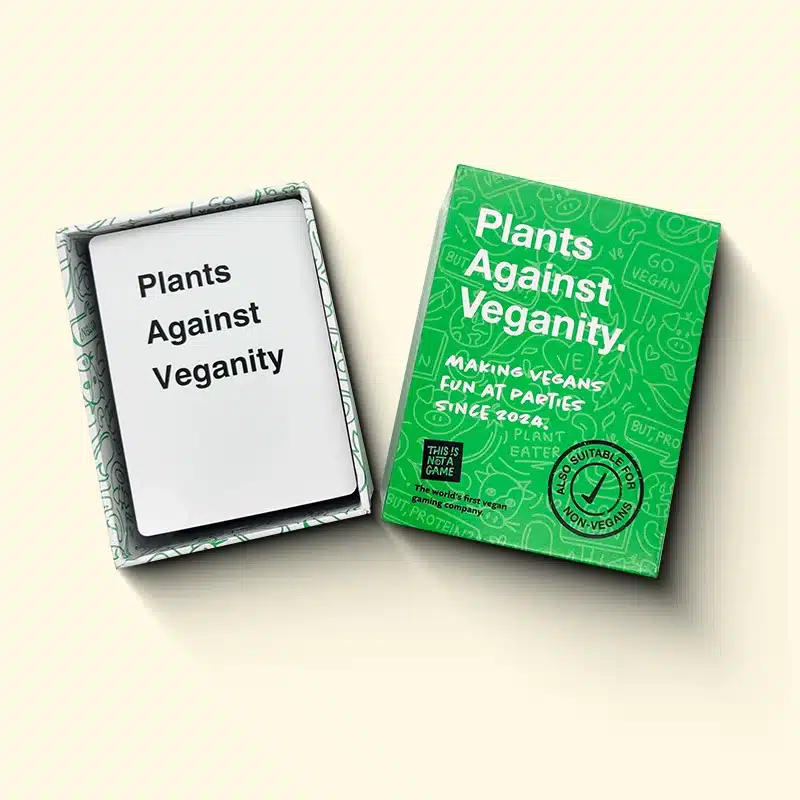

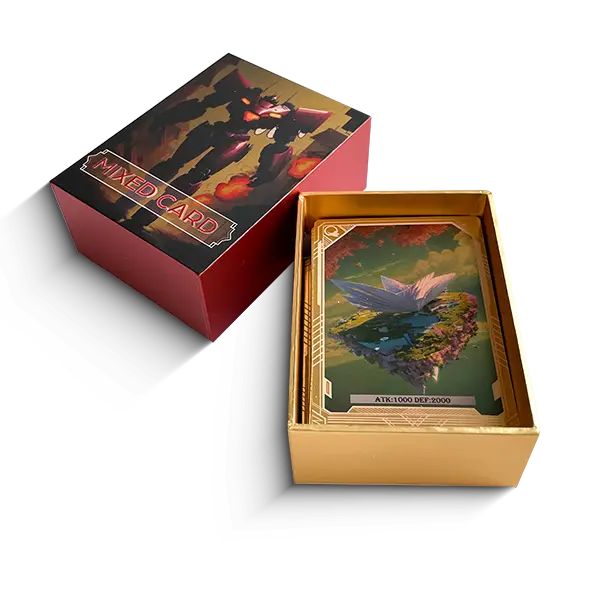

Packaging and Booster Packs

Packaging not only protects your game cards but also reinforces your branding and enhances the user experience. We offer a full range of packaging options to match your game’s format and branding.

Tuck end box

A lightweight, economical box style with flaps that fold into each end, ideal for smaller decks and retail packaging.

Telescope rigid box

A sturdy two-piece box with a separate lid and base, offering premium protection and presentation.

Magnetic closure rigid box

A premium rigid box with a magnetic flap that snaps shut, perfect for collector's editions or high-end game sets.

Shoulder Neck Rigid Box

A premium two-piece box with a raised inner tray (shoulder) for added depth and a sleek, elegant unboxing experience.

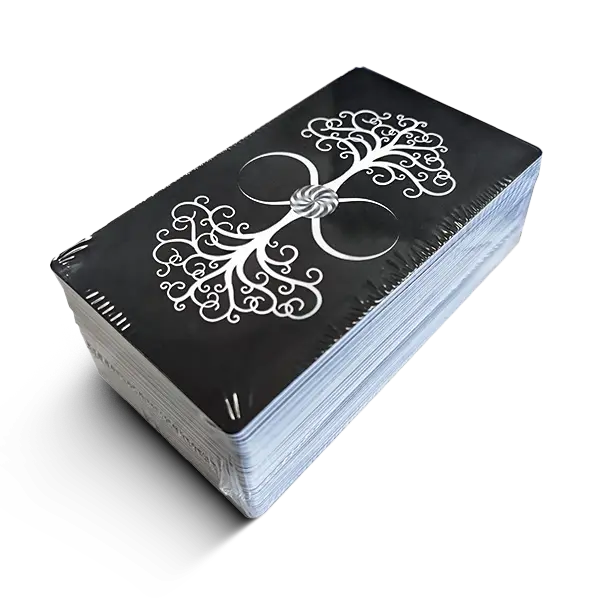

Shrink-wrapped decks

Sealed in a tight, clear plastic film for protection during shipping or as a simple retail-ready option.

Booster Packs

If you're releasing collectible card sets, we can produce booster packs with randomized or sequential card assortments.

Why Choose QinPrinting for Game Card Printing?

Choosing the right partner for your custom game card printing project is critical to the success of your game. At QinPrinting, we combine technical precision with responsive customer support and global logistics to help you deliver a professional product, on time and on budget. Whether you’re a first-time creator or an established publisher, we’re here to make every step smooth, reliable, and efficient.

Offset printing expertise

We print large volumes with sharp detail and accurate colors

Free file checking

We manually inspect every file before production

Custom card counts and sizes

Mix and match deck types with no extra handling fee

Secure collation

Automatic card machines ensure correct order and safe packaging

Eco-friendly options

FSC-certified paper, soy inks, and recycled materials available

Full-service packaging

We handle everything from card printing to box assembly

Global shipping

We deliver worldwide with air, sea, and combined freight options

These advantages make QinPrinting one of the most trusted providers of game card printing services internationally. We take pride in helping your ideas succeed—beautifully printed, precisely packed, and ready for play.

FAQs

How much does it cost to print a game card deck?

To help you quickly estimate the cost of your custom game cards, we’ve provided some sample pricing below. By reviewing these price lists, you’ll notice that ordering larger quantities can be more cost-effective. For a personalized quote on any custom size, simply click the Instant Online Quote button.

2.5" x 3.5" Game Card Printing Price Chart

| Quantity | 200 decks | 500 decks | 1000 decks | 2000 decks | 5000 decks | 10000 decks |

|---|---|---|---|---|---|---|

| 56 cards/deck |

$3.50 each $700 total |

$1.68 each $840 total |

$1.13 each $1,126 total |

$0.85 each $1,700 total |

$0.69 each $3,454 total |

$0.66 each $6,585 total |

| 80 cards/deck |

$4.98 each $996 total |

$2.47 each $1,236 total |

$1.64 each $1,640 total |

$1.22 each $2,449 total |

$0.98 each $4,909 total |

$0.92 each $9,226 total |

| 100 cards/deck |

$5.21 each $1,042 total |

$2.70 each $1,351 total |

$1.87 each $1,866 total |

$1.42 each $2,838 total |

$1.17 each $5,828 total |

$1.10 each $11,042 total |

| 120 cards/deck |

$5.61 each $1,122 total |

$2.99 each $1,494 total |

$2.11 each $2,114 total |

$1.68 each $3,354 total |

$1.42 each $7,118 total |

$1.34 each $13,396 total |

| 160 cards/deck |

$7.16 each $1,432 total |

$3.79 each $1,895 total |

$2.67 each $2,666 total |

$2.06 each $4,126 total |

$1.72 each $8,600 total |

$1.65 each $16,495 total |

| 200 cards/deck |

$7.81 each $1,561 total |

$4.26 each $2,130 total |

$3.08 each $3,077 total |

$2.49 each $4,974 total |

$2.14 each $10,716 total |

$2.09 each $20,938 total |

- 300 gsm / 110 lb premium cardstock with varnish both sides, rounded corners

- Please note that all prices are EXW (Ex Works) our facility and do not include shipping costs.

What is the minimum order quantity?

The minimum order quantity (MOQ) for cards is a competitive 200 units.

Can I choose a custom design for the front and back of the card?

Yes! You can fully customize both the front and back of the cards with your designs. We also offer design assistance if you need help bringing with any aspect of the process.

How long does it take to print and ship custom game cards?

Standard production time is 2 to 3 weeks depending on complexity. We’ll provide estimated delivery timelines once we confirm your order details.

Can I order a sample deck before mass production?

Yes, you can order a sample deck. We offer various proofing options to help you review the design, colors, paper type, and print quality of the final product.

If you’re unsure about our paper types, and finishes, or want to see examples of past projects, you can also request a paper sample pack for reference so that you know exactly what you’re getting.

What file format should I use for custom card designs?

Use high-resolution PDF files in CMYK color mode, include 3 mm bleed, and separate artwork from die lines. Detailed instructions are available in our template guide.

Can I order a sample deck before printing?

Yes. We offer physical samples and proofing options so you can review the materials and print quality before placing a full order.

Do you ship internationally?

Yes, we offer global delivery, including North America, Europe, Asia, and Australia. Shipping methods include standard air, sea, and combined freight.

QinPrinting Reviews

Warm regards, Patricia Anderson

The communication was clear and responsive, the quality of the final product exceeded our expectations, and the entire process felt smooth and well managed. QinPrinting was a pleasure to work with, and we would absolutely collaborate with them again.

The end experience and product is also exemplary. Well packed, high quality printing.

I also want to call out their designer in particular - excellent attention to detail, and caught quite a few things before approving the print.

Fantastic.

I was nervous and unsure of everything. Nelson was so patient and respectful and replied promptly. It took years for me to complete but I was so happy for his service and patient manner. Cards look beautiful and feedback was excellent from people.Will definitely contact again for next project.

Talk to Us

Ready to print your own custom game cards? Whether you’re designing board game cards, custom trading card decks, or educational tools, QinPrinting offers expert support, fast turnaround, and outstanding print quality. Contact us today for a free quote and personalized consultation.