Packaging Support

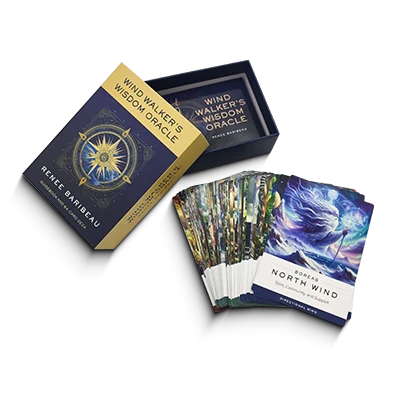

With over 25 years of experience, we create all kinds of packaging: folding cartons, rigid boxes, corrugated boxes, display boxes, sleeves, and more. Our team works with clients worldwide to deliver custom solutions for every industry and budget.

Below you’ll find quick guides to key packaging terms, processes, and finishes. Explore each topic to learn more, and if you have questions, we’re always happy to help.

Design & Materials

Explore essential guides to packaging design, production, and finishes. Each section links to detailed resources for deeper reference.

Free ready-to-use dielines for different box styles.

Guidelines for file setup, color, and resolution.

Coated paper, textured paper, colored paper, and specialist papers, PVC, foam and more

Reverse, straight, and top tuck boxes, auto, snap-lock, and more.

Detailed box layouts that define folds, cuts, and structure.

Gloss / matte / soft-touch lamination, emboss, deboss, foil stamping, and more.

Structural samples, prototypes, and production proofs.

Production & Engineering

See the sections below to dive deeper into each aspect of production and engineering.

Offset, UV, and screen printing techniques.

Functional design, durability, and assembly.

How we support your custom box artwork design.

Box dimensions, surface area and volume

FAQ

We are an offset printing company, so printing is the core service we provide. We do not provide a comprehensive design service. However, unlike many printers, we are committed to offering significant design support. For example, we offer free design templates for cardboard box, rigid box, and more, along with an expert artwork file checking service and, of course, one-to-one advice and assistance for all our customers via telephone, email, Skype, and the online chat.

We need high-resolution PDF formatted artwork (including a 3 mm bleed zone) for printing. Photos and images should be exported as vectors or with a resolution of at least 300 dpi to guarantee professional quality results.

Offset printing uses the CMYK color space. Most design software uses the RGB color space. The most efficient solution is for you to change the color space to CMYK when you export your print-ready files. If you don’t know how to do this, ask us and we’ll explain. But don’t worry too much. If we receive your artwork in RGB mode, we’ll change it for you before we go to press.

You can send us your artwork via email, to [email protected], or send us a link to Dropbox, Google Docs, etc. You can also upload your files to file sharing sites such as Sprend or Wetransfer and share the link with us.

We pride ourselves on the quality of our work and our commitment to providing the best possible service to all our customers. We have developed a range of rigorous quality control protocols designed to make sure that all our products are printed to the highest standards and leave our facilities in perfect condition. We have passed the GB/T19001–2008 IDT ISO9001:2008 Quality Management System Certification for excellence in our quality controls. We will be delighted to show you our certificates on request.