Custom Playing Card Printing

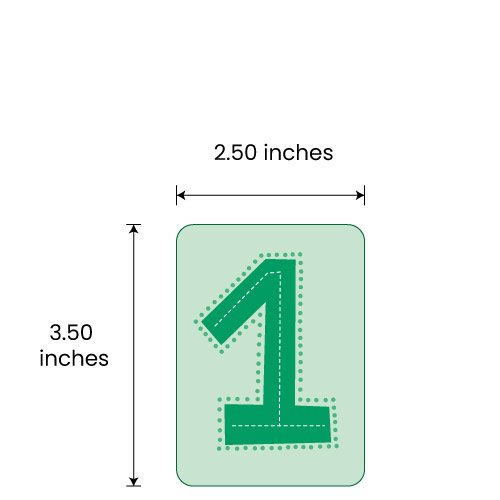

At QinPrinting, we can produce the standard 52-card poker deck—54 if you include a pair of promotional cards—each measuring 2.5″ x 3.5″ or custom size and packaged in a traditional tuck-end box. However, our specialty lies in crafting custom-made decks and custom playing card boxes based on your unique designs. These personalized decks are a popular choice for magic trick manufacturers, offer a memorable corporate gift, and serve as distinctive direct-to-market retail products.

Playing Card Instant Quote

based on your choices

Paper Options

We offer two common types of paper for custom playing cards: black core paper and premium cardstock. Each has its own advantages depending on your needs.

Black Core Paper

Black core paper is specially designed to prevent light from passing through the cards. This ensures that no information is visible from the reverse side, making it the preferred choice for professional poker and other games where fairness is essential. The standard weight we use is:

| Paper | Weight | Thickness (mm) | Thickness (pt) |

|---|---|---|---|

| Black Core Paper | 310gsm | 0.325mm | 13pt |

Premium Cardstock

Premium cardstock is slightly thicker than standard paper, giving your playing cards extra strength and durability. It’s a versatile choice that works well for casual games, educational cards, or collectible decks. The available weights are:

If you’re looking for specialty papers—such as holographic paper, colored paper, or pearlescent paper—please contact us for a custom solution.

Surface Finishes

We generally recommend applying a varnish to both sides of the cards and using rounded corners to ensure a smooth, protective finish. However, depending on how and where your cards will be used, you may prefer one of our other available surface treatments. Below are the various card finish options for reference.

A non-glossy coating on both sides that offers a textured feel.

A glossy coating on both sides with a subtle texture.

A smooth, velvety matte film applied to both sides, offering durable, non-reflective finish.

A shiny film applied to both sides, giving the card a sleek, high-gloss appearance.

A glossy finish applied to specific areas for a bold and distinct look.

Metallic gold foil pressed onto the card for an elegant, eye-catching detail.

Metallic silver foil applied to the card, adding a sleek, reflective accent.

Raised designs for added texture and elegance.

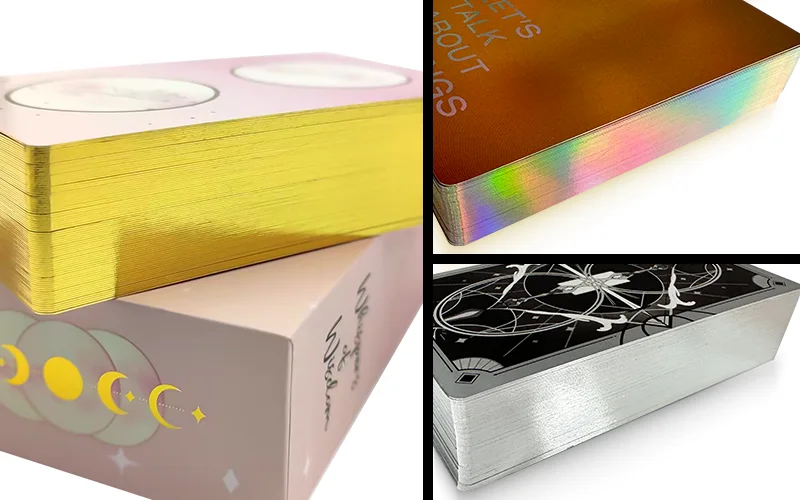

Metallic foil applied to the edges of the card, creating a premium and polished look from every angle.

Printed on holographic paper, which reflects rainbow-like colors when viewed from different angles.

Custom Playing Card Sizes

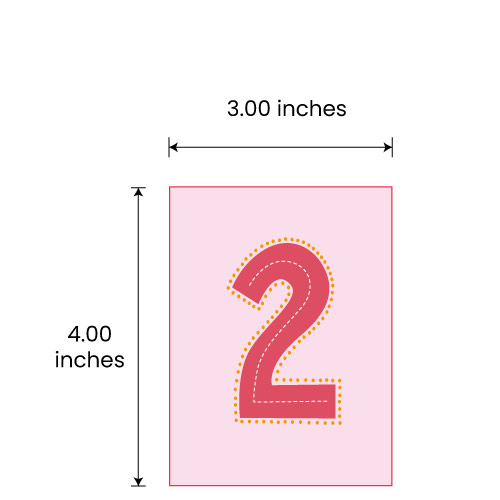

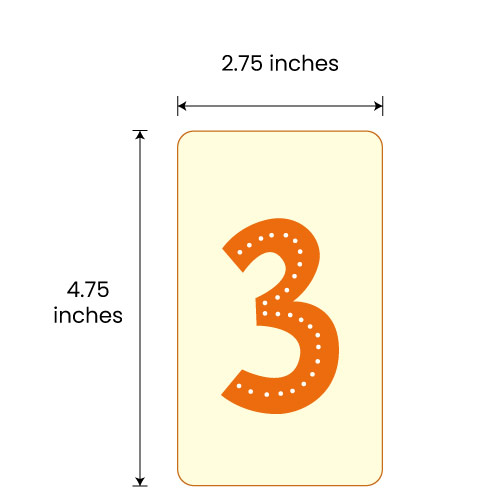

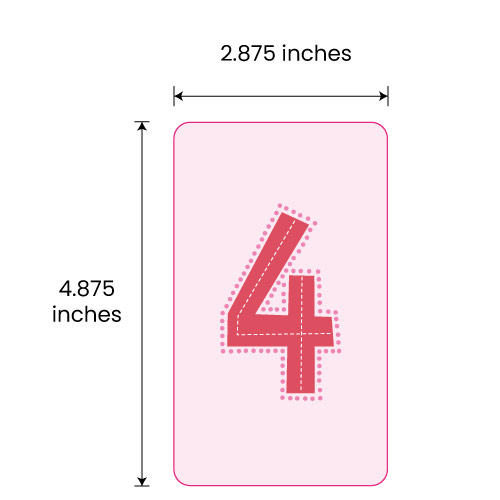

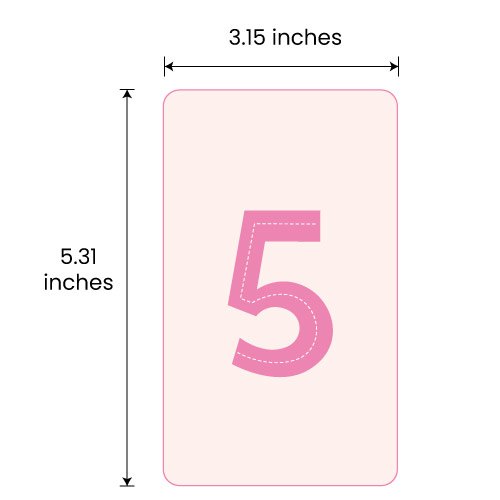

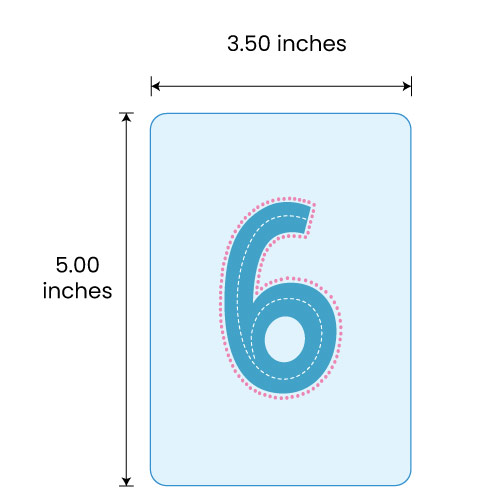

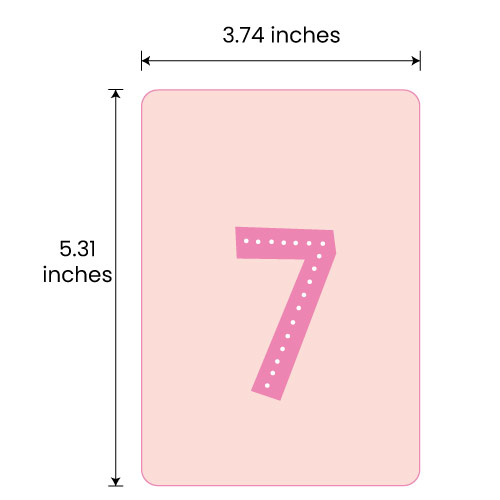

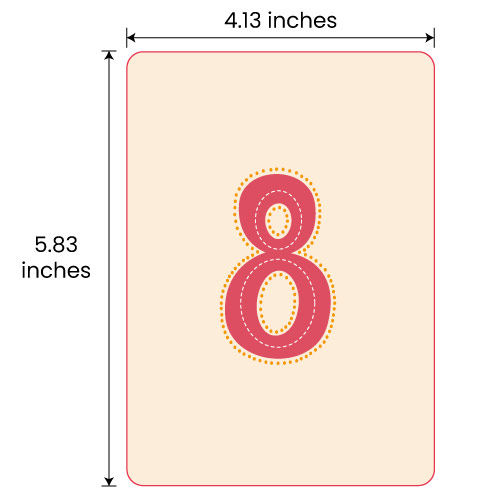

The standard size for traditional playing cards is 2.5″ x 3.5″ and is always the most popular. It’s also the most economical as we have the die-cutting molds for this size of card always in stock, so there’s no need to pay an added mold-making fee. However, if you prefer a unique size for a specific project, we can accommodate that as well. Below are some sample playing card sizes for reference.

Need something custom? No problem. We can create new molds for any playing card size or shape.

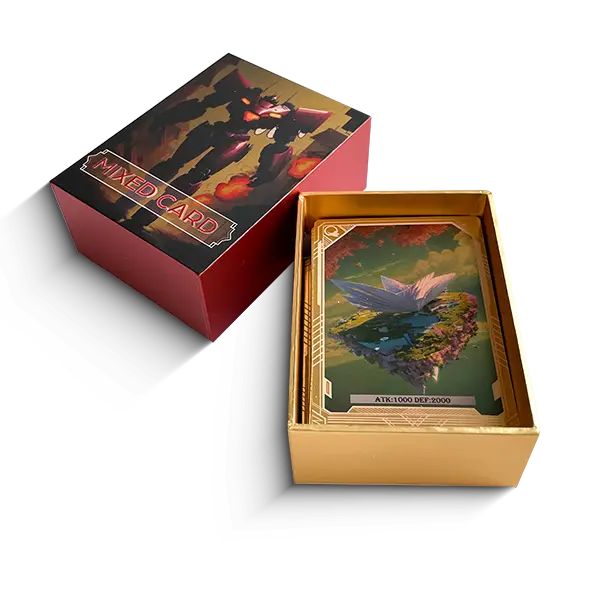

Custom Playing Card Boxes

The common playing card decks are packaged in a tuck-end box before being shrink-wrapped. However, if you want your cards to look unique in the market, you can choose from the following custom playing card box options. Meanwhile, for any specific design in your mind, we can work together to create a fully customized solution based on your ideas. The possibilities are truly unlimited!

Tuck end box

Lightweight and cost-effective. Flaps fold into each end—great for small decks and simple retail display.

Telescope rigid box

A two-piece box with separate lid and base. Rigid, sturdy, and ideal for mid-range sets with a focus on presentation.

Magnetic closure rigid box

A premium option with a magnetic flap that keeps the box securely shut. Great for high-end educational kits or retail products.

Shoulder Neck Rigid Box

Offers an elevated unboxing experience. Features an interior tray (shoulder) that adds depth and structure.

Shrink-wrapped decks

Clean, transparent wrapping that protects the cards during shipping and offers a simple retail-ready solution.

Booster Packs

We also offer sealed packs with randomized or sequential card sets, ideal for gamified educational products or collector sets.

Need accessories? We can include sticker sheets, card rings, elastic bands, or printed booklets—tailored to your flash card goals.

We’re always happy to discuss new formats or unusual specifications. If you don’t see what you’re looking for above, get in touch. Our team will be glad to help.

Why Print Your Playing Cards with Us?

- Aside from our experience and expertise, we offer an unparalleled level of personal customer service and unbeatable pricing.

- We also use state-of-the-art printing technology and offer a range of environmentally friendly options, including recycled paper and card, FSC-certification, biodegradable soy inks, and more.

- We won’t charge you for die-cut molds if you choose our standard 2.5″ x 3.5″ size.

- Our expert team will check all your files free as part of the service and we have rigorous quality control protocols “baked in” to our design and manufacturing systems—including weight-checking your finished package to make sure no cards have gone missing—so we can guarantee a perfect result every time.

- Our advanced automatic card machine technology means that your cards are collected and collated as you want them with no risk of loss or damage, and are always in the right order.

- We can assemble your completed decks and load them into your custom branded box of choice, including either a standard tuck-end box, a telescope rigid box, or a magnetic closure rigid box.

FAQs

How much does it cost to print a flash card deck?

To help you quickly estimate the cost of your custom playing cards, we’ve provided some sample pricing below. By reviewing these price lists, you’ll notice that ordering larger quantities can be more cost-effective. For a personalized quote on any custom size, simply click the Instant Online Quote button.

| Quantity | 200 decks | 500 decks | 1000 decks | 2000 decks | 3000 decks | 5000 decks | 10000 decks |

|---|---|---|---|---|---|---|---|

| Price | Unit: $4.67 Total: $933 |

Unit: $2.16 Total: $1,081 |

Unit: $1.38 Total: $1,379 |

Unit: $0.93 Total: $1,978 |

Unit: $0.88 Total: $2,630 |

Unit: $0.76 Total: $3,811 |

Unit: $0.70 Total: $7,033 |

- Please note that all prices are EXW (Ex Works) our facility and do not include shipping costs.

What is the minimum order quantity for custom playing card printing?

Our minimum order quantity for custom playing card printing is typically 200 decks.

What is the standard size for custom playing cards?

The standard size for playing cards is 2.5″ x 3.5″ (63mm x 88mm), which is commonly used in most card games. However, we can accommodate custom sizes if you have specific dimensions in mind for your project.

What types of paper are used for printing custom playing cards?

Common options include 300gsm (11pt) gloss art paper, 310gsm (13pt) black core paper, and 350gsm (16pt) gloss art cardstock, which provide the perfect balance of thickness and flexibility for easy shuffling and long-lasting use.

Can I create my own design for playing cards?

Yes! You can fully customize your playing card design. We offer playing card templates to help guide your design, but you have complete control over the artwork, card faces, backs, and even the design of specialty cards like the joker playing card.

How to prepare files for playing card printing?

We share a few important tips.

- Export your files in PDF format for printing

- Make sure that you change the color space from RGB to CMYK before you export

- If you’re exporting bitmaps from Photoshop, for example — then make sure that you set the image resolution to 300 dpi

- If you have a design with colors or images which extend all the way to the edge of the finished sticker, remember to add a 3 mm “bleed zone” to allow for die-cutting

If you’re working with a professional designer to create your files, they should understand what’s needed to make everything “print ready”. But if you’re working with design software yourself for the first time, these are the vital tips to remember before you submit your files. Still, our team of experts will always manually check all your files before we go to press. If we find any issues, we’ll let you know and help you resolve them.

How long does it take to print playing cards?

The production timeline typically ranges from 2-3 weeks, depending on the complexity of your order. Shipping times vary by location, but we provide estimated delivery dates upon order confirmation.

Can I get a sample of my custom playing cards before placing a full order?

Yes, we offer sample prints so you can see and feel your cards before placing a larger order.

If you’re unsure about our paper types, finishes, or want to see examples of past projects, you can also request a paper sample pack for reference. This ensures you’re fully confident before moving forward with your order!

Do you ship internationally?

Yes, we ship worldwide, including to the USA, Canada, Europe, and Australia. We offer various shipping options, including combined sea and air freight, to suit your budget and timeline.

QinPrinting Reviews

The e-transfer payment seems fishy but they followed through on all asks so was totally fine! We just received our first batch and our getting ready to launch our product! Will definitely be restocking with Qin Printing again!

Susan!!!! These books are SOOOOOOO beautiful! I don't think we could have dreamed how joyful it would be to open the box and find such care for and beautifully printed books. This was a special day -- we hope to have many more like it.

Thank you for fielding so many questions. Your patience with us (well, me) was so kind. You and your team have gone above and beyond for us.

Gratefully,

MAC

Their product quality, attention to detail, and clear communication have exceeded my expectations at every step. I truly appreciate their dedication and care, and I’m looking forward to collaborating with them on many more projects to come.